-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

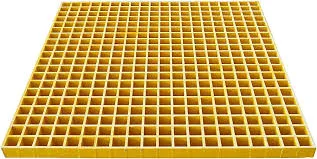

FRP Insulated Tanks for Enhanced Efficiency and Durability in Industrial Applications

Understanding FRP Insulation Tanks Benefits and Applications

Fiberglass Reinforced Plastic (FRP) insulation tanks are increasingly becoming popular in various industries due to their unique properties and advantages. Constructed from a polymer matrix reinforced with fibers, usually fiberglass, these tanks are designed to offer superior insulation and durability, making them an ideal choice for a wide range of applications.

Advantages of FRP Insulation Tanks

One of the primary benefits of FRP insulation tanks is their excellent thermal insulation properties. The use of fiberglass in the construction of these tanks provides a low thermal conductivity, which means that they can effectively maintain the temperature of the contents, whether hot or cold. This is particularly advantageous in industries where temperature-sensitive materials need to be stored or transported. For example, in the chemical and food industries, maintaining a consistent temperature is crucial for quality and safety.

Moreover, FRP insulation tanks are lightweight compared to traditional materials like metal. This characteristic not only makes them easier to handle and install but also reduces transportation costs. Their lightweight nature does not compromise their strength; in fact, FRP tanks boast a high strength-to-weight ratio, making them robust and durable under various conditions.

Corrosion resistance is another significant advantage of FRP insulation tanks. Unlike metal tanks that can corrode over time, especially when exposed to harsh chemicals, FRP tanks resist chemical degradation, thereby extending their lifespan. This property makes them especially suitable for the storage of acids, bases, and other corrosive substances commonly found in industrial applications.

Applications of FRP Insulation Tanks

frp insulation tank

FRP insulation tanks are versatile and can be used in various settings. In the oil and gas industry, for instance, they are employed to store crude oil and other hydrocarbons, safeguarding against temperature fluctuations and chemical exposure. The pharmaceutical industry also benefits from these tanks, where the controlled environment is critical for the storage of sensitive drugs and chemicals.

In the food and beverage sector, FRP insulation tanks are an excellent choice for storing liquids such as juices, milk, and other perishable goods. The tanks maintain the required temperature, ensuring that the products remain fresh and safe for consumption. Additionally, their non-reactive surfaces prevent contamination, making them ideal for applications where hygiene is a top priority.

Environmental Considerations

With an increasing emphasis on sustainability, the environmental impact of materials used in industrial settings is under scrutiny. FRP insulation tanks are often considered environmentally friendly due to their longevity and low maintenance needs, which can reduce the frequency of replacement and disposal. Furthermore, the energy efficiency gained from improved insulation can lead to reduced energy consumption, aligning with global efforts to minimize environmental footprints.

Conclusion

In conclusion, FRP insulation tanks serve a vital role in various industries by providing an effective solution for temperature control, durability, and corrosion resistance. Their lightweight nature, combined with excellent insulation properties, make them an ideal choice for a wide range of applications. As industries continue to seek efficient and sustainable solutions, the demand for FRP insulation tanks is likely to grow, solidifying their place as a valuable asset in modern industrial operations. Whether it’s in chemical production, food preservation, or oil storage, FRP insulation tanks offer reliability and efficiency that can significantly enhance operational performance.