-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

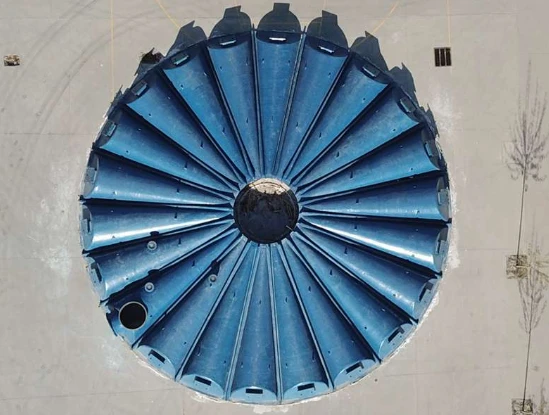

frp ladder

The Concept of an FRP Ladder A Step Towards Innovation and Safety

In the world of material science and engineering, Fiber Reinforced Polymer (FRP) has emerged as a revolutionary alternative to traditional materials. One of the most practical applications of FRP lies in the design and fabrication of ladders. An FRP ladder represents a significant leap forward in safety, durability, and versatility. This article will explore the features, benefits, and potential applications of FRP ladders, highlighting their importance in today’s industrial and construction environments.

Understanding FRP

Fiber Reinforced Polymer is a composite material made by combining a polymer resin with reinforcing fibers such as glass, carbon, or aramid. The result is a lightweight yet incredibly strong material that can withstand harsh conditions, making it ideal for a variety of applications. When it comes to ladders, the use of FRP provides favorable advantages compared to traditional materials like wood or aluminum.

Safety First

One of the primary reasons for the increasing adoption of FRP ladders in various industries is their enhanced safety features. FRP is non-conductive, which is particularly beneficial for electrical work, as it minimizes the risk of electric shocks. Furthermore, the material does not corrode, rust, or deteriorate over time, ensuring consistent reliability and a longer lifespan. Additionally, FRP ladders have a slip-resistant surface, providing extra grip and stability for users, even in wet or oily conditions.

Lightweight and Portable

Another significant advantage of FRP ladders is their lightweight nature. Unlike their metal counterparts, which can be cumbersome to carry and maneuver, FRP ladders can be easily transported without sacrificing strength. This feature is especially valuable in industries where mobility is essential, such as construction and maintenance work. Workers can transport these ladders with ease, making them a practical choice for tasks that require frequent relocation.

frp ladder

Versatility in Design

FRP ladders can be customized to meet a wide range of specifications, allowing for tailored solutions that fit within any project’s requirements. They can be designed in various lengths, sizes, and configurations, including straight ladders, step ladders, and extension ladders. The versatility of FRP material allows for innovative designs that can include portability features like foldability, making them even more convenient for users.

Environmental Resistance

FRP ladders boast exceptional resistance to environmental factors. Unlike wood, which can rot, or aluminum, which can corrode, FRP is impervious to moisture, UV rays, and many chemicals. This characteristic makes FRP ladders suitable for use in diverse environments, from construction sites to chemical plants, where exposure to harsh substances is common. The ability to maintain their integrity in challenging conditions further positions FRP ladders as a superior choice.

Cost-Effectiveness over Time

While the initial investment in FRP ladders may be higher than that of traditional materials, the long-term savings are substantial. With no need for frequent repairs or replacements due to corrosion and wear, FRP ladders can often provide a lower total cost of ownership. Their durability and performance ultimately result in fewer accidents and downtime, making them a cost-effective solution for businesses focused on efficiency and safety.

Conclusion

In conclusion, FRP ladders are not only a remarkable example of innovation in material science but also a practical solution for various industries seeking safety, portability, and durability. Their unique properties make them a preferred choice for professionals across sectors, from construction to electrical work. As industries continue to evolve, the transition to advanced materials like FRP will undoubtedly play a crucial role in shaping safer, more efficient work environments. The FRP ladder stands tall as a testament to the progress we can achieve when we embrace new technologies and prioritize safety in our designs.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025