-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp ladder

Understanding the FRP Ladder A Versatile Tool for Various Applications

The FRP (Fiber Reinforced Plastic) ladder has gained popularity in many sectors due to its numerous advantages over traditional materials like wood or metal. Composed of a polymer matrix that is reinforced with fibrous materials, FRP presents a unique combination of strength, durability, and lightweight characteristics. This article delves into the features, benefits, and applications of FRP ladders.

The Composition and Design of FRP Ladders

FRP ladders are constructed using a combination of glass or carbon fibers and a resin matrix, typically epoxy or polyester, which hardens to form a robust structure. The fibers provide tensile strength, while the resin binds everything together, offering resistance against various environmental factors. The design can vary from simple step ladders to more complex configurations for industrial or commercial use, making them highly versatile.

One notable feature of FRP ladders is their non-conductive nature, making them safe to use in environments with electrical hazards. This quality is particularly crucial in industries where workers can encounter high voltages, such as utilities and telecommunications. Furthermore, FRP is resistant to corrosion, rust, and degradation from chemicals, which is vital for applications in harsh or corrosive environments such as chemical plants or outdoor settings.

Advantages of FRP Ladders

1. Lightweight One of the primary benefits of FRP ladders is their lightweight nature. Weighing significantly less than aluminum or wooden ladders, they are easier to transport and maneuver, reducing the physical strain on workers.

2. Durability FRP materials exhibit remarkable resistance to wear and tear, outlasting traditional ladders in many cases. They can endure extreme temperatures and harsh weather conditions without deteriorating, ensuring a long service life.

3. Safety Features Many FRP ladders come with additional safety features such as slip-resistant steps, ensuring that users have better footing. Their non-conductive properties further minimize risks associated with electrical accidents.

frp ladder

4. Low Maintenance Unlike wooden ladders that require regular treatment to prevent rot or metal ladders that can corrode, FRP ladders require minimal upkeep. A simple wash with soap and water is often sufficient to keep them in good condition.

Applications of FRP Ladders

The versatility of FRP ladders allows them to be utilized in a wide range of industries. They are commonly found in

- Industrial Settings For maintenance tasks in factories or warehouses, where safety and durability are paramount. - Utilities In the electric and telecommunications sectors, workers use FRP ladders for installing or repairing infrastructure without the risk of electrical conductivity.

- Construction Sites FRP ladders are beneficial on construction sites due to their lightweight and robust nature, enabling easy handling while ensuring safety.

- Marine Applications The resistance to corrosion makes FRP ladders ideal for use on boats and offshore platforms where exposure to saltwater is a concern.

- Recreational Use They are also popular for residential and recreational applications, such as pools and gardens, where durability and safety are essential.

Conclusion

In summary, FRP ladders are an exceptional tool in various applications due to their combination of strength, safety, and durability. Their lightweight and non-conductive properties make them a preferred choice in many industrial settings, while their low maintenance and corrosion resistance ensure long-lasting performance. As industries continue to adapt to modern materials, the FRP ladder stands out as a reliable and versatile option that meets the demands of today’s work environments. Whether for industrial, commercial, or recreational use, FRP ladders are poised to remain an essential tool for many years to come.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

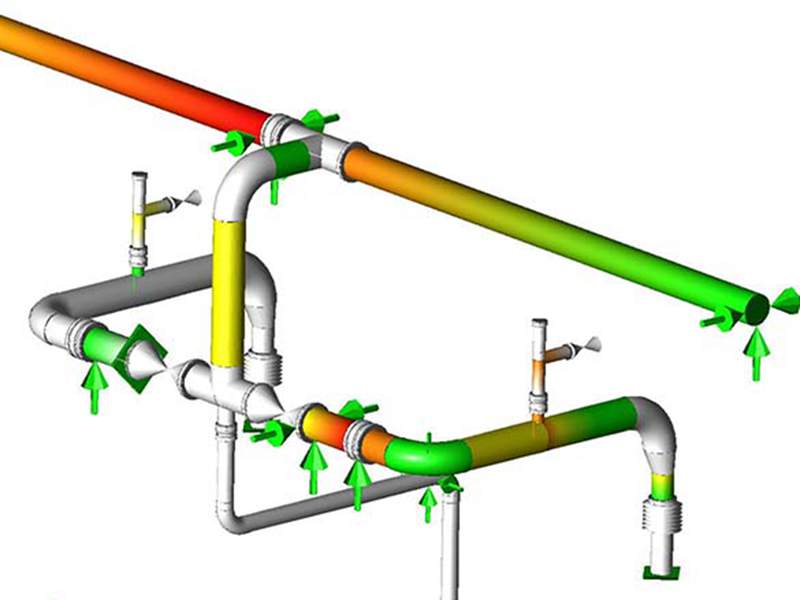

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025