-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Approaches to Enhanced Water Treatment Systems in Industrial Applications

The Future of Frp Launder Innovations and Trends in Wastewater Treatment

In today's world, the increasing concern for environmental sustainability has pushed industries to explore innovative solutions for waste management. One such solution is the adoption of Fiber Reinforced Polymer (FRP) launder systems in wastewater treatment facilities. These systems are designed to improve the efficiency of water treatment processes while minimizing environmental impact. This article will explore the concept of FRP launders, their advantages, and emerging trends in this field.

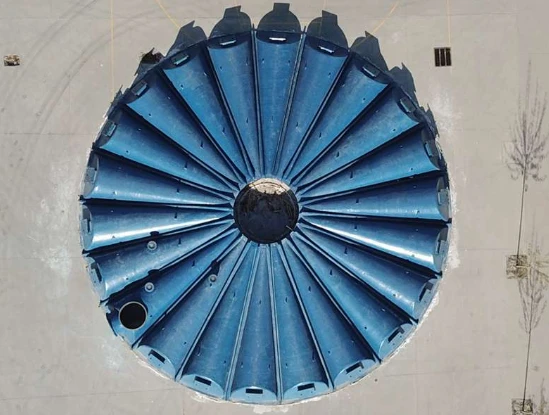

Understanding FRP Launder

FRP launders are channels or troughs used to collect and transport treated water from settling tanks, clarifiers, or other water treatment processes. Made from fiber-reinforced polymers, these launders offer a durable and lightweight alternative to traditional materials such as concrete or metal. The design of FRP launders can be customized to suit various applications, enhancing their effectiveness in diverse settings.

Advantages of FRP Launder Systems

1. Corrosion Resistance One of the primary benefits of using FRP in launder systems is its resistance to corrosion. Traditional materials like steel are prone to rusting, especially in the harsh chemical environment of wastewater treatment. FRP, on the other hand, withstands these conditions, ensuring a longer lifespan for the equipment.

2. Lightweight and Easy Installation Compared to traditional materials, FRP is significantly lighter, making it easier and less costly to transport and install. This characteristic allows for reduced labor costs and shorter installation times, making it an attractive option for wastewater treatment plants looking to upgrade their infrastructure.

3. Customizable Design FRP launders can be tailored to meet specific requirements, including varying shapes and sizes. This flexibility enables engineers to design systems that maximize efficiency and functionality while effectively integrating into existing treatment processes.

4. Enhanced Flow Management The smooth surface finish of FRP lowers friction, allowing for improved water flow. This characteristic also minimizes the risk of clogging, ensuring a consistent and reliable flow of treated water.

5. Sustainability By switching to FRP launders, wastewater treatment facilities can reduce their carbon footprint. The manufacturing process of FRP is often more environmentally friendly compared to traditional materials, and the durability of FRP means that less frequent replacements are necessary, further contributing to sustainability.

frp launder

Emerging Trends in FRP Launder Technology

The water treatment industry is constantly evolving, and several trends are emerging that may shape the future of FRP launder systems

1. Integration of Smart Technology As industries move toward automation and smart technologies, the integration of sensors and monitoring systems into FRP launders is becoming more prevalent. These technologies can provide real-time data on flow rates, water quality, and system maintenance, facilitating more efficient operations and proactive management.

2. Modular Systems The trend towards modular design in wastewater treatment facilities allows for greater flexibility and scalability. FRP launders are often well-suited for modular applications, enabling plants to easily expand their capacity in response to growing demand without a complete overhaul of existing systems.

3. Increased Focus on Energy Efficiency With the rising costs of energy and the push for greener practices, wastewater treatment facilities are seeking energy-efficient solutions. FRP launders can be designed to minimize energy use during water transport, incorporating features that reduce pump energy consumption.

4. Advanced Composite Materials The development of new composite materials promises even greater performance for FRP launders. Innovations may lead to materials with improved mechanical properties, better resistance to chemicals, and enhanced durability.

5. Regulatory and Market Support As governments implement stricter regulations on wastewater treatment and environmental practices, the market for efficient and sustainable solutions like FRP launders is likely to grow. This regulatory support can drive research and development, leading to further innovations.

Conclusion

FRP launder systems represent a significant advancement in wastewater treatment technology, offering a combination of durability, efficiency, and environmental sustainability. As industries continue to innovate and seek solutions that align with a greener future, the role of FRP launders will likely become increasingly important. Embracing these advancements can lead to improved outcomes in wastewater treatment processes, benefiting both the environment and the communities that rely on clean water.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025