-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp materials for heat and nuclear power applications

FRP Materials for Heat and Nuclear Power Applications

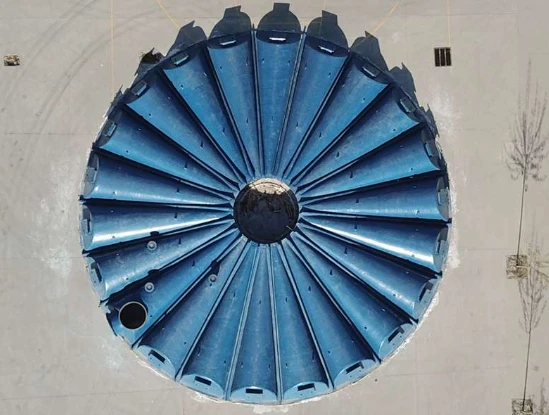

Fiber Reinforced Polymer (FRP) materials have emerged as essential components in various sectors, particularly in heat and nuclear power applications. Their advanced properties, including high strength-to-weight ratios, corrosion resistance, and thermal insulation capabilities, make them ideal for the harsh environments typically found in power generation facilities. This article explores the characteristics, benefits, and emerging applications of FRP materials in the context of heat and nuclear power.

Understanding FRP Materials

FRP consists of a polymer matrix reinforced with fibers, which can be glass, carbon, aramid, or natural fibers. The combination of these materials results in a composite with significantly enhanced mechanical properties compared to traditional materials such as metals or wood. The polymer matrix provides flexibility while the fibers contribute strength and rigidity. The lightweight nature of FRP makes it easier to handle and install, further reducing labor costs and increasing efficiency in construction and maintenance.

Thermal Properties and Applications

In heat power applications, FRP materials are utilized for their excellent thermal insulation properties. These composites can be formulated to withstand high temperatures while minimizing heat loss. This property is particularly vital in energy-efficient designs, where maintaining optimal operating temperatures can lead to improved efficiency and reduced operational costs. FRP materials are commonly used in the construction of insulation panels for boilers, heat exchangers, and piping systems, ensuring that heat is retained effectively and that energy loss is minimized.

Nuclear Power Applications

The nuclear power industry presents unique challenges due to the extreme conditions within reactors and the need for materials that can withstand radiation exposure over long periods. FRP materials are increasingly being considered for various components in nuclear reactors, such as shielding, structural supports, and piping. Their corrosion resistance ensures longevity, especially in environments where traditional materials may deteriorate. Additionally, the lightweight nature of FRP facilitates easier installation, reducing the risk of accidents during transport and construction.

frp materials for heat and nuclear power applications

Special attention must be paid to the formulation of FRP materials used in nuclear applications. The materials must be designed to maintain their mechanical integrity under radiation, high temperatures, and other challenging conditions. Innovative formulations are being developed to enhance the radiation resistance of FRP composites, thus extending their usability in nuclear environments.

Corrosion Resistance and Maintenance

One of the most significant advantages of FRP materials is their exceptional resistance to corrosion. In both heat and nuclear power plants, exposure to various chemicals and high-humidity environments can lead to severe degradation of conventional materials. FRP’s ability to resist such corrosion not only extends the lifespan of components but also reduces the need for frequent maintenance and replacements. This feature is particularly crucial for components that are difficult to access or replace, such as underground piping or high-altitude installations.

Economic Benefits

The economic benefits of using FRP materials in power generation are considerable. Reduced maintenance costs, lower energy losses due to improved insulation, and the longevity of materials contribute to overall lifecycle savings. Furthermore, the lightweight construction of FRP reduces the costs associated with transportation and installation, making it an appealing choice for project managers.

Future Outlook

The future of FRP materials in heat and nuclear power applications looks promising. Ongoing research continues to enhance the performance characteristics and environmental sustainability of these materials. As the demand for energy-efficient solutions increases, and as safety regulations tighten within the nuclear sector, the adoption of FRP materials is likely to expand.

In conclusion, Fiber Reinforced Polymer materials represent a transformative solution for the heat and nuclear power industries. Their unique properties, including thermal insulation, corrosion resistance, and lightweight design, offer significant advantages over traditional materials. As innovations continue to enhance the performance of these composites, FRPs stand poised to play a critical role in the future of energy generation, helping to create safer, more efficient, and environmentally friendly power plants. The integration of FRP materials into power generation not only underscores the advancements in engineering and materials science but also aligns with the global push towards sustainable energy practices.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025