-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 23, 2025 04:26

Back to list

Oblate Tanks

Fiber Reinforced Polymer (FRP) materials have increasingly become a cornerstone in the innovative world of heat and nuclear power applications. Their unique properties, blending strength with light weight and resistance, create solutions previously unattainable with traditional materials. In the realm of these high-stakes industries, FRPs offer unparalleled advantages that not only propel efficiencies but also advance sustainability and safety standards.

The integration of FRP materials into heat and nuclear power applications is supported by a robust portfolio of successful projects and studies. For example, in the refurbishment of heat exchangers, FRP components have demonstrated superior performance over traditional alloys, offering increased thermal conductivity and durability. Furthermore, the versatility of FRP is evidenced in its application for constructing storage tanks and pressure vessels, where its chemical resistance and strength-to-weight ratio outperform traditional options. Despite the remarkable advantages of FRP materials, expertise in their application is essential to maximize their benefits. Engineering teams intending to incorporate FRPs must possess a thorough understanding of composite science, including the interplay of fiber type, matrix properties, and environmental factors affecting performance. Collaborations with certified professionals in composite technology ensure that solutions are not only effective but also comply with industry standards and regulations. The credibility of FRP materials in these high-risk industries is underscored by endorsements from authoritative bodies and ongoing research initiatives aimed at further optimizing their properties. Trust in these materials is built upon a foundation of rigorous testing and continuous innovation, ensuring that the newest FRP composites meet the evolving needs of heat and nuclear power challenges. In conclusion, the application of FRP materials in heat and nuclear power industries marks a transformational shift towards safer, more sustainable, and cost-effective operations. By leveraging their unique properties, these composites address long-standing challenges while paving the way for future advancements. As the industry continues to innovate, FRP materials stand poised to play a pivotal role in shaping a resilient and efficient energy landscape.

The integration of FRP materials into heat and nuclear power applications is supported by a robust portfolio of successful projects and studies. For example, in the refurbishment of heat exchangers, FRP components have demonstrated superior performance over traditional alloys, offering increased thermal conductivity and durability. Furthermore, the versatility of FRP is evidenced in its application for constructing storage tanks and pressure vessels, where its chemical resistance and strength-to-weight ratio outperform traditional options. Despite the remarkable advantages of FRP materials, expertise in their application is essential to maximize their benefits. Engineering teams intending to incorporate FRPs must possess a thorough understanding of composite science, including the interplay of fiber type, matrix properties, and environmental factors affecting performance. Collaborations with certified professionals in composite technology ensure that solutions are not only effective but also comply with industry standards and regulations. The credibility of FRP materials in these high-risk industries is underscored by endorsements from authoritative bodies and ongoing research initiatives aimed at further optimizing their properties. Trust in these materials is built upon a foundation of rigorous testing and continuous innovation, ensuring that the newest FRP composites meet the evolving needs of heat and nuclear power challenges. In conclusion, the application of FRP materials in heat and nuclear power industries marks a transformational shift towards safer, more sustainable, and cost-effective operations. By leveraging their unique properties, these composites address long-standing challenges while paving the way for future advancements. As the industry continues to innovate, FRP materials stand poised to play a pivotal role in shaping a resilient and efficient energy landscape.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

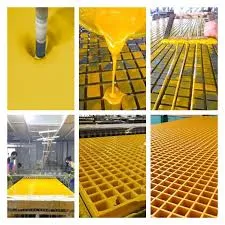

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025