-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 11, 2025 17:32

Back to list

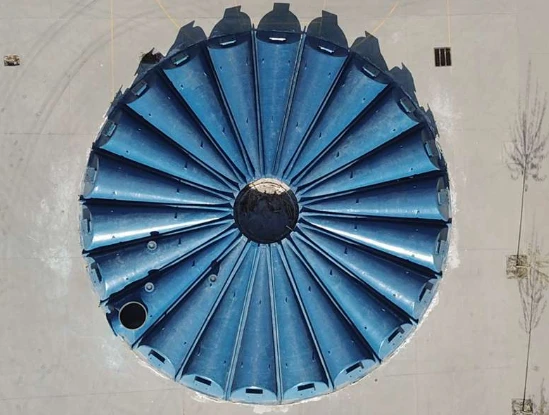

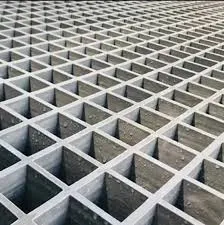

frp materials for heat and nuclear power applications

Fiber-reinforced plastics (FRP) have emerged as a vital solution for modern heat and nuclear power applications, providing a unique synthesis of expertise, trustworthiness, and innovative engineering. These materials, known for their impressive strength-to-weight ratio, corrosion resistance, and thermal stability, have become indispensable in these critical industries.

The authoritativeness of FRP materials is bolstered by extensive research and field studies. Peer-reviewed studies have consistently demonstrated their resilience in high-temperature environments, affirming their suitability for demanding applications. Regulatory endorsements and certifications from international bodies, including the American Society of Mechanical Engineers (ASME) and the International Atomic Energy Agency (IAEA), further validate their use in critical infrastructure. Trustworthiness in the application of FRP is reinforced by real-world success stories. Numerous nuclear facilities worldwide have adopted FRP solutions, reporting improved performance and enhanced safety metrics. Feedback from engineers and technicians confirms their reliability and effectiveness, fostering confidence among industry stakeholders. As industries continue to seek sustainable and effective solutions for energy production, the role of FRP materials is anticipated to grow. Ongoing research and development aim to expand their capabilities, introducing innovations such as nanocomposite enhancements for even greater strength and versatility. Furthermore, the inherent recyclability of certain FRP components aligns with global sustainability goals, positioning them as a forward-thinking choice for environmentally conscious enterprises. In summary, FRP materials provide an unparalleled combination of expertise, reliability, and performance in heat and nuclear power applications. Their demonstrated effectiveness, coupled with industry endorsements, positions them as a cornerstone of modern infrastructure. As advancements in composite technology progress, the advantages of FRP materials are set to redefine benchmarks for safety, efficiency, and sustainability in these critical industries.

The authoritativeness of FRP materials is bolstered by extensive research and field studies. Peer-reviewed studies have consistently demonstrated their resilience in high-temperature environments, affirming their suitability for demanding applications. Regulatory endorsements and certifications from international bodies, including the American Society of Mechanical Engineers (ASME) and the International Atomic Energy Agency (IAEA), further validate their use in critical infrastructure. Trustworthiness in the application of FRP is reinforced by real-world success stories. Numerous nuclear facilities worldwide have adopted FRP solutions, reporting improved performance and enhanced safety metrics. Feedback from engineers and technicians confirms their reliability and effectiveness, fostering confidence among industry stakeholders. As industries continue to seek sustainable and effective solutions for energy production, the role of FRP materials is anticipated to grow. Ongoing research and development aim to expand their capabilities, introducing innovations such as nanocomposite enhancements for even greater strength and versatility. Furthermore, the inherent recyclability of certain FRP components aligns with global sustainability goals, positioning them as a forward-thinking choice for environmentally conscious enterprises. In summary, FRP materials provide an unparalleled combination of expertise, reliability, and performance in heat and nuclear power applications. Their demonstrated effectiveness, coupled with industry endorsements, positions them as a cornerstone of modern infrastructure. As advancements in composite technology progress, the advantages of FRP materials are set to redefine benchmarks for safety, efficiency, and sustainability in these critical industries.

Related Products