-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp mining equipment

Exploring FRP Mining Equipment Innovations and Applications

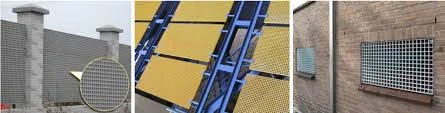

The mining industry, integral to global economies, constantly seeks improvements in efficiency and safety. One of the emerging innovations in this field is the use of Fiber Reinforced Polymer (FRP) materials in mining equipment. These materials, which have revolutionized various sectors, are now making significant inroads into mining, offering a combination of lightweight properties, corrosion resistance, and high strength.

Exploring FRP Mining Equipment Innovations and Applications

Additionally, FRP's exceptional resistance to corrosion is a critical advantage in mining environments, where exposure to chemicals, dust, and moisture is common. Traditional materials, especially metals, are prone to deterioration over time, resulting in frequent maintenance and replacement costs. With FRP, mining companies can enjoy longer service life for their equipment, leading to reduced downtime and more operational efficiency. This is particularly relevant in environments such as coal mining sites, which often involve the use of water sprays and chemical treatments that could corrode conventional equipment.

frp mining equipment

The versatility of FRP also allows it to be molded into complex shapes and sizes, enabling the design of customized mining solutions. For example, FRP can be used in the production of specialized conveyor systems, pump housings, and protective linings for chutes and pipes. These tailored designs are essential for improving material handling processes and increasing throughput in mining operations.

Moreover, the application of FRP extends beyond just equipment. It has significant implications for the safety and health of mining professionals. The reduced weight of tools and machinery can lead to lesser physical strain on workers, thereby mitigating risks associated with manual handling and equipment operation. Additionally, FRP materials do not conduct electricity, providing a further layer of safety in environments where electrical hazards may exist.

The future of FRP in the mining industry looks promising, as advancements in manufacturing techniques and material science continue to open new avenues for application. Research is ongoing to improve the durability and performance characteristics of FRP, for instance, enhancing its fire resistance and impact toughness. Furthermore, the growing emphasis on sustainable mining practices will likely drive more companies to adopt materials that are not only efficient but also environmentally friendly.

In conclusion, FRP mining equipment represents a significant step forward in addressing the challenges faced by the mining industry. With advantages like lightweight construction, corrosion resistance, customization potential, and improved worker safety, FRP is poised to become a staple in the design and manufacturing of mining machinery. As the industry evolves, integrating these advanced materials will facilitate greater efficiency, sustainability, and safety in mining operations worldwide.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025