-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 30, 2025 01:52

Back to list

frp mining equipment

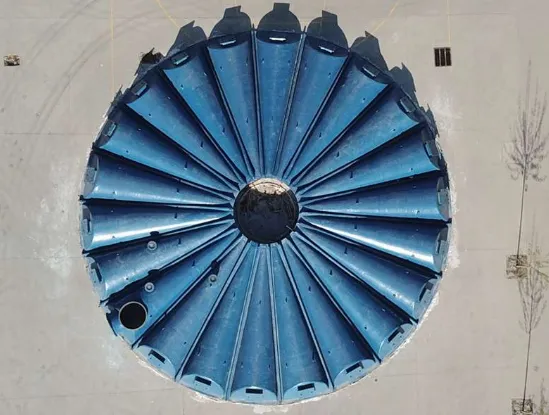

Fiberglass Reinforced Plastic (FRP) mining equipment is a revolutionary innovation in the mining industry, offering durability, resistance to harsh environments, and a lightweight alternative to traditional materials. FRP materials are composed of a polymer matrix reinforced with fibers, typically glass, aramid, or carbon. These materials offer exceptional advantages over conventional metals and are increasingly being adopted for various mining applications.

For mining companies focusing on sustainability, FRP offers an eco-friendly construction option. The manufacturing process has a lower environmental impact compared to metals, and the durability of FRP means equipment does not need to be replaced as frequently, reducing waste. This aligns with global trends towards sustainable and responsible mining practices, making FRP a compelling choice for companies looking to improve their environmental profile. In terms of expertise, numerous case studies and industrial applications have validated the performance of FRP in mining settings. For instance, several large-scale mining companies have reported reduced operational costs and increased service life of their equipment after transitioning parts of their operations to FRP materials. These first-hand accounts from industry leaders highlight the professional endorsement of FRP mining equipment as a technologically superior alternative. Moreover, manufacturers of FRP mining equipment often provide detailed consultation and customization services, allowing clients to tailor products to their specific needs and conditions. This level of expertise and customization enhances the professional relationship between supplier and client, ensuring the equipment performs optimally in its intended environment. In conclusion, the shift towards FRP mining equipment represents a significant advancement in the mining industry. The material offers an unmatched combination of durability, lightweight structure, resistance to harsh conditions, and environmental benefits. As a product class, FRP mining equipment is supported by substantial experience and authoritative endorsements from professionals within the industry. Given the evidence and growing trend, it is clear that FRP stands to elevate operational efficiency and sustainability in mining applications, marking it as a pivotal component in the future of mining technologies.

For mining companies focusing on sustainability, FRP offers an eco-friendly construction option. The manufacturing process has a lower environmental impact compared to metals, and the durability of FRP means equipment does not need to be replaced as frequently, reducing waste. This aligns with global trends towards sustainable and responsible mining practices, making FRP a compelling choice for companies looking to improve their environmental profile. In terms of expertise, numerous case studies and industrial applications have validated the performance of FRP in mining settings. For instance, several large-scale mining companies have reported reduced operational costs and increased service life of their equipment after transitioning parts of their operations to FRP materials. These first-hand accounts from industry leaders highlight the professional endorsement of FRP mining equipment as a technologically superior alternative. Moreover, manufacturers of FRP mining equipment often provide detailed consultation and customization services, allowing clients to tailor products to their specific needs and conditions. This level of expertise and customization enhances the professional relationship between supplier and client, ensuring the equipment performs optimally in its intended environment. In conclusion, the shift towards FRP mining equipment represents a significant advancement in the mining industry. The material offers an unmatched combination of durability, lightweight structure, resistance to harsh conditions, and environmental benefits. As a product class, FRP mining equipment is supported by substantial experience and authoritative endorsements from professionals within the industry. Given the evidence and growing trend, it is clear that FRP stands to elevate operational efficiency and sustainability in mining applications, marking it as a pivotal component in the future of mining technologies.

Related Products