-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Effective Solutions for Managing Moisture in FRP Applications

Understanding FRP Moisture Traps A Comprehensive Overview

Fiber-Reinforced Polymer (FRP) materials have gained significant traction in various industries due to their unique properties, such as high strength-to-weight ratios, corrosion resistance, and flexibility in design. However, one of the challenges that these materials face is moisture absorption, which can lead to various forms of degradation. Hence, the introduction of FRP moisture traps has become crucial in extending the lifespan and enhancing the performance of FRP components.

Understanding FRP Moisture Traps A Comprehensive Overview

One of the primary benefits of using FRP moisture traps is that they help maintain the mechanical properties of the polymer. When moisture is absorbed into the FRP matrix, it can lead to a reduction in tensile and flexural strength. In some cases, moisture intrusion can initiate a process known as hydrolysis, whereby the chemical bonds within the polymer are weakened. This can result in delamination, loss of structural integrity, and even failure of the component under load. By integrating moisture traps, we can effectively mitigate these risks, ensuring that the performance standards of the FRP material are upheld.

frp moisture trap

Additionally, moisture traps can significantly influence the thermal properties of FRP components. Moisture within a polymer matrix can act as a heat conductor, altering the thermal profile of the material over time. This change can affect the thermal expansion and contraction behavior of the FRP, potentially leading to warping or cracking due to differential thermal stresses. By utilizing moisture traps, we can ensure that the thermal characteristics of the FRP remain stable, thereby preserving its intended functionality and lifespan.

The design of moisture traps can vary based on the specific application, but they generally consist of hygroscopic materials or coatings that can effectively absorb and hold moisture. Common materials used for moisture traps include silica gel, zeolites, and various polymers engineered for enhanced moisture absorption. These materials are often incorporated into the FRP matrix during the manufacturing process, enabling a seamless integration that does not compromise the structural properties of the composite.

Moreover, it is important for engineers and designers to assess the environmental conditions and loading scenarios the FRP components will face. This assessment will guide the selection of appropriate moisture trap materials and their placement within the composite structure. For instance, in applications exposed to highly dynamic water flows, moisture traps may require specific configurations or sizes to maximize their efficiency.

In conclusion, FRP moisture traps play an essential role in the longevity and reliability of fiber-reinforced polymer materials. By actively managing moisture intrusion, these innovative solutions uphold the mechanical and thermal properties of FRP structures, ensuring they perform optimally even under challenging environmental conditions. With the growing reliance on FRP materials across various industries, the incorporation of effective moisture management strategies will become increasingly vital in safeguarding the integrity and durability of these advanced composites. As research and development in this field continue to evolve, we can expect even more efficient and effective moisture trap technologies to emerge, further enhancing the capabilities of FRP materials.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

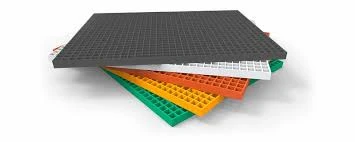

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025