-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

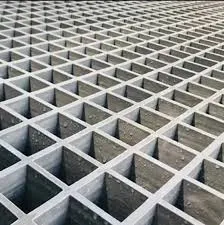

frp panel

Understanding FRP Panels A Comprehensive Overview

Fiberglass Reinforced Plastic (FRP) panels are innovative materials increasingly used in various industries due to their unique properties and advantages. Comprising a polymer matrix reinforced with glass fibers, these panels offer a perfect blend of strength, flexibility, and resistance to environmental factors. This article delves into the composition, benefits, and applications of FRP panels, highlighting why they have become a favored choice in modern construction and manufacturing.

Composition of FRP Panels

FRP panels are constructed from a thermosetting resin, typically polyester or vinyl ester, combined with glass fibers. The fibers are the reinforcing phase, providing the necessary strength and rigidity, while the resin acts as a binder allowing for shape retention and protection from external elements. The manufacturing process usually involves techniques such as hand lay-up, spray-up, or vacuum infusion, which contribute to the overall quality and durability of the final product.

Advantages of FRP Panels

1. Corrosion Resistance One of the most significant advantages of FRP panels is their excellent resistance to corrosion. Unlike traditional materials such as wood or steel, which can deteriorate when exposed to moisture, chemicals, or extreme weather conditions, FRP panels remain intact, making them ideal for use in environments prone to corrosion.

2. Lightweight and Durable Despite their lightweight nature, FRP panels exhibit a high strength-to-weight ratio, meaning they can withstand significant loads without being cumbersome. This characteristic simplifies transportation and installation, reducing overall project costs.

3. Thermal Insulation FRP panels possess excellent thermal insulation properties, helping to maintain stable indoor temperatures and reducing energy costs. This feature is particularly beneficial in applications involving temperature-sensitive products or environments.

4. Aesthetic Flexibility Available in a variety of colors, patterns, and finishes, FRP panels offer considerable design versatility. Manufacturers can fabricate panels that resemble traditional materials, such as wood or stone, allowing architects and designers to achieve desired aesthetics without sacrificing functionality.

5. Low Maintenance Given their resilience and robustness, FRP panels require minimal maintenance. Their surface can be easily cleaned, and they do not need regular treatments or coatings like paint, which can fade or peel over time.

frp panel

Applications of FRP Panels

FRP panels find utility in numerous sectors, including

- Construction In buildings, FRP panels serve as exterior cladding, interior walls, and roofing materials. Their resistance to moisture and termites makes them suitable for areas prone to damp conditions.

- Transportation In the automotive and aerospace industries, FRP panels are used to manufacture lightweight components that improve fuel efficiency without compromising structural integrity.

- Food Processing The hygiene and easy cleanability of FRP panels make them ideal for food processing facilities. Their non-porous surface prevents bacterial growth, ensuring compliance with health regulations.

- Marine Applications With their exceptional corrosion resistance, FRP panels are widely employed in the marine industry for boat construction and repairs, where exposure to saltwater can significantly damage conventional materials.

- Renewable Energy FRP panels are increasingly being used in the manufacture of wind turbine blades and other renewable energy applications due to their lightweight and durable properties.

Conclusion

In summary, FRP panels represent a significant advancement in material technology, offering a combination of strength, flexibility, and resistance to environmental factors that traditional materials often lack. Their versatility ensures they can cater to various needs across multiple industries, making them an indispensable asset in modern manufacturing and construction. As technology advances, the applications and benefits of FRP panels are likely to expand further, solidifying their role in sustainable and efficient building practices.