-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

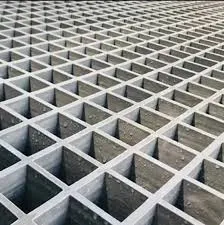

frp pipe saddle

Understanding FRP Pipe Saddles Their Importance and Applications

FRP (Fiber Reinforced Plastic) pipe saddles are critical components used across various industrial applications, especially in the realms of oil and gas, water treatment, and chemical processing. As industries strive for efficiency, durability, and versatility in their infrastructure, FRP materials have emerged as a popular choice. This article delves into the significance of FRP pipe saddles, their construction, benefits, and various applications.

What is FRP?

Before analyzing FRP pipe saddles, it is vital to understand what FRP is. Fiber Reinforced Plastic (FRP) is a composite material comprised of a polymer matrix reinforced with fibers, such as glass, carbon, or aramid. This combination yields a material that is lightweight yet extremely strong, corrosion-resistant, and suitable for various environmental conditions.

Construction of FRP Pipe Saddles

FRP pipe saddles are designed to provide stability and support for pipes in various settings. They are typically fabricated through a process of molding, where the reinforcing fibers are saturated with resin and then shaped into the saddle form. This form is crucial as it allows the saddle to fit snugly around the pipe, distributing weight evenly and reducing stress concentrations.

The manufacturing of FRP saddles often utilizes advanced techniques, such as pultrusion or hand lay-up, which enable precise control over the fiber orientation and resin application. These techniques not only contribute to the strength and rigidity of the saddles but also enhance their resistance to environmental factors such as UV radiation, chemicals, and moisture.

Benefits of Using FRP Pipe Saddles

1. Corrosion Resistance One of the most significant advantages of FRP materials is their resistance to corrosion. Unlike metal components, FRP pipe saddles do not rust or degrade when exposed to harsh chemicals or moisture, leading to an extended lifespan.

2. Lightweight Nature FRP saddles are much lighter compared to their metal counterparts, making them easier to handle and install. This lightweight nature reduces labor costs and can simplify logistics during transportation and installation.

3. Cost-Effective Solutions While the initial cost of FRP materials can be higher than traditional options, their long-term durability and reduced maintenance requirements make them a cost-effective choice in the long run.

frp pipe saddle

4. Versatility in Design FRP saddles can be customized to meet specific operational requirements, allowing industries to design solutions that fit their unique piping systems. This adaptability is particularly beneficial in complex installations.

5. Insulation Properties FRP does not conduct electricity, making FRP pipe saddles an excellent choice for industries that deal with sensitive electrical equipment or hazardous materials.

Applications of FRP Pipe Saddles

FRP pipe saddles find utility in various sectors, including

- Oil and Gas Industry In oil and gas operations, FRP pipe saddles support pipelines that transport corrosive substances. Their durability under extreme conditions makes them ideal.

- Water Treatment Facilities FRP materials are widely used in water treatment due to their non-toxic nature and resistance to biofouling, ensuring that the water remains uncontaminated.

- Chemical Processing Plants The chemical industry frequently employs FRP saddles for their ability to withstand aggressive chemicals, reducing the risk of leaks and failures.

- Marine Applications In marine environments, FRP saddles resist saltwater corrosion, making them suitable for installations on offshore platforms and ships.

Conclusion

In conclusion, FRP pipe saddles are an indispensable component across various industries, offering a host of benefits such as corrosion resistance, lightweight construction, and design versatility. As industries continue to prioritize sustainability and efficiency, the adoption of FRP materials is likely to grow, making FRP pipe saddles a critical focus for future developments in piping systems. Their superior performance in demanding environments ensures that they will remain integral to modern infrastructure for years to come.