-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp pipes and fittings

FRP Pipes and Fittings A Comprehensive Overview

Fiber Reinforced Plastic (FRP) pipes and fittings have emerged as a revolutionary solution in various industries, particularly in water management, chemical processing, and construction. Their unique combination of lightweight, strength, and corrosion resistance makes them a preferred choice for many applications where traditional materials like metal or concrete may fail.

Advantages of FRP Pipes

One of the most significant advantages of FRP pipes is their resistance to corrosion. Unlike metal pipes that rust over time in harsh environments, FRP pipes are designed to withstand chemicals, salts, and biological agents. This property is especially crucial in industries such as wastewater management and chemical processing, where exposure to corrosive substances is commonplace.

Additionally, FRP pipes are lightweight, making them easier to handle and install. This advantage not only reduces labor costs but also minimizes the need for heavy machinery during installation, particularly in remote or difficult-to-access locations. The flexibility of FRP also allows for easier integration into existing systems, further enhancing their appeal.

Durability and Longevity

Durability is another hallmark of FRP pipes. These pipes can last significantly longer than traditional materials, often exceeding 50 years with proper care. This longevity translates to lower maintenance costs and reduced frequency of replacements, making FRP a cost-effective solution in the long run.

frp pipes and fittings

Moreover, FRP pipes can withstand extreme temperatures and pressures, making them suitable for various applications—from transporting hot fluids in industrial plants to handling high-pressure water in municipal systems. Their ability to maintain structural integrity in demanding conditions is a key reason for their increasing adoption across multiple sectors.

Fittings and Accessories

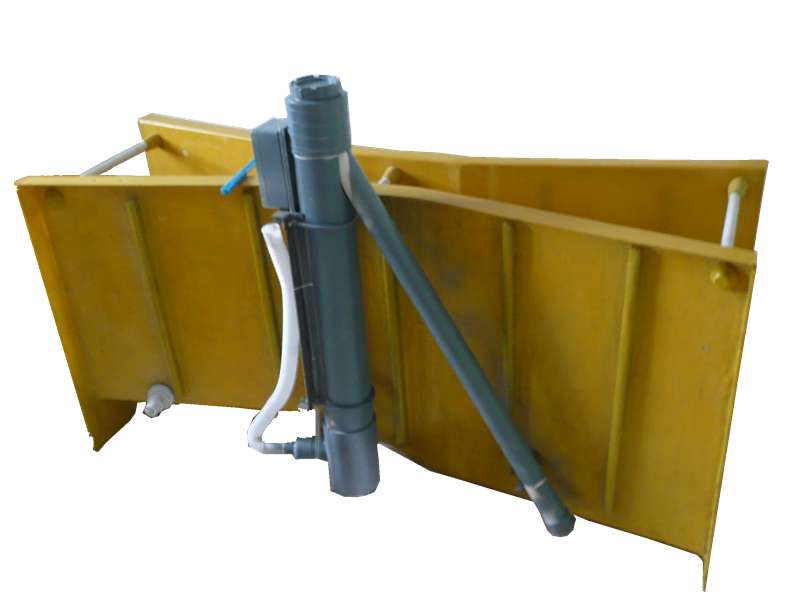

To maximize the potential of FRP pipes, a range of fittings and accessories have been developed to ensure seamless integration into pipe systems. These fittings, including elbows, tees, flanges, and couplers, are designed with the same attention to durability and corrosion resistance as the pipes themselves. They are often manufactured using advanced techniques that allow for precise fit and function, ensuring that joints and connections are robust and leak-proof.

Environmental Considerations

In addition to their technical advantages, FRP pipes and fittings also benefit the environment. Their lightweight nature reduces transportation emissions, while their long lifespan minimizes resource consumption over time. Furthermore, many manufacturers are focusing on sustainable production practices, incorporating recycled materials into their products, thus contributing to a circular economy.

Conclusion

In summary, FRP pipes and fittings represent a forward-thinking solution for industries facing the challenges of corrosion, weight, and durability. As technology continues to advance, we can expect even more innovative applications and improvements in FRP products, further solidifying their role as indispensable components in modern infrastructure. With their proven performance and environmental benefits, FRP pipes are indeed shaping the future of piping systems.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025