-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 15, 2025 20:52

Back to list

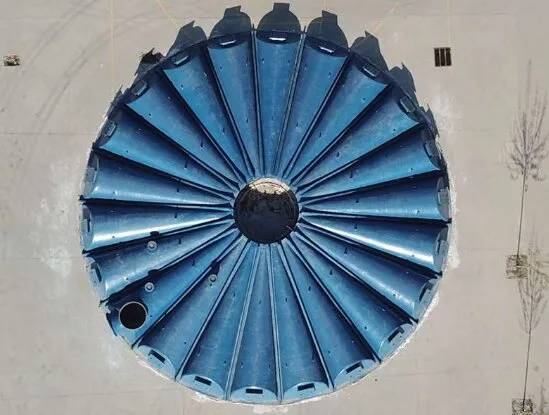

frp pipes and fittings

FRP pipes and fittings have become indispensable components in various industries due to their unmatched durability, resistance to environmental stresses, and adaptability to different applications. Fiber Reinforced Plastic (FRP) is a composite material made from a polymer matrix reinforced with fibers, typically glass fibers, which grants it unique properties that are highly valuable in challenging environments.

In terms of authority, FRP’s role in sustainable engineering solutions cannot be ignored. As industries move towards greener practices, the environmentally friendly nature of FRP emerges as a pivotal advantage. Companies looking to achieve their sustainability goals adopt FRP products due to their long service life, which minimizes the need for frequent replacements, thus reducing waste. Additionally, manufacturing processes for FRP can be adapted to lower energy consumption, further contributing to a company’s environmental objectives. When it comes to trustworthiness, the real-world performance of FRP pipes and fittings speaks volumes. Many field studies and real-life applications provide evidence of their long-term reliability. Industrial users consistently report decreased maintenance and downtime when switching from traditional materials to FRP, bolstering their confidence in these products. Case studies detailing the successful implementation of FRP solutions, alongside testimonials from engineers and industry veterans, reinforce the trust industries place in FRP. Customization is another key area where FRP pipes and fittings excel. Manufacturers can cater to specific needs by tailoring the composition and configuration of FRP components. This flexibility allows industries to procure products that precisely meet their operational requirements, from complex bending to unique size specifications. As industries evolve and face new challenges, the ability to custom-design FRP solutions fosters a sense of innovation and progression. In conclusion, FRP pipes and fittings represent a robust solution in the realm of industrial materials. Their blend of corrosion resistance, lightweight properties, and customizable features make them an ideal choice for a wide range of applications. The comprehensive expertise and authority demonstrated by FRP in various settings establish it as a formidable choice for engineers and industry professionals seeking performance and reliability. As the push toward sustainable practices continues, FRP stands out as a trustworthy, forward-thinking material choice.

In terms of authority, FRP’s role in sustainable engineering solutions cannot be ignored. As industries move towards greener practices, the environmentally friendly nature of FRP emerges as a pivotal advantage. Companies looking to achieve their sustainability goals adopt FRP products due to their long service life, which minimizes the need for frequent replacements, thus reducing waste. Additionally, manufacturing processes for FRP can be adapted to lower energy consumption, further contributing to a company’s environmental objectives. When it comes to trustworthiness, the real-world performance of FRP pipes and fittings speaks volumes. Many field studies and real-life applications provide evidence of their long-term reliability. Industrial users consistently report decreased maintenance and downtime when switching from traditional materials to FRP, bolstering their confidence in these products. Case studies detailing the successful implementation of FRP solutions, alongside testimonials from engineers and industry veterans, reinforce the trust industries place in FRP. Customization is another key area where FRP pipes and fittings excel. Manufacturers can cater to specific needs by tailoring the composition and configuration of FRP components. This flexibility allows industries to procure products that precisely meet their operational requirements, from complex bending to unique size specifications. As industries evolve and face new challenges, the ability to custom-design FRP solutions fosters a sense of innovation and progression. In conclusion, FRP pipes and fittings represent a robust solution in the realm of industrial materials. Their blend of corrosion resistance, lightweight properties, and customizable features make them an ideal choice for a wide range of applications. The comprehensive expertise and authority demonstrated by FRP in various settings establish it as a formidable choice for engineers and industry professionals seeking performance and reliability. As the push toward sustainable practices continues, FRP stands out as a trustworthy, forward-thinking material choice.

Related Products