-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp pipes and fittings for ship building

The Role of FRP Pipes and Fittings in Shipbuilding

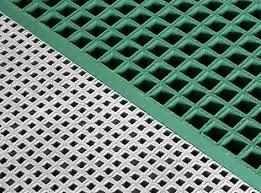

In the maritime industry, the materials used in shipbuilding are crucial for ensuring durability, safety, and efficiency. Among the various materials, Fiberglass Reinforced Plastic (FRP) has emerged as a highly favored choice for pipes and fittings. FRP’s unique properties make it particularly suited for the harsh marine environment, providing a range of advantages that traditional materials cannot offer.

One of the most significant benefits of FRP pipes and fittings is their corrosion resistance. Ships operate in saline environments, where exposure to saltwater can lead to rapid deterioration of metal components. FRP, on the other hand, is resistant to corrosion, which greatly extends the lifespan of pipes and fittings and reduces maintenance costs over time. This feature is essential in ensuring that ships remain operational without frequent repairs or replacements.

Moreover, FRP materials are lightweight compared to conventional metal options, such as steel or aluminum. This lightweight nature has profound implications for shipbuilding, as it allows for more efficient weight distribution and improved fuel efficiency. Reducing the overall weight of a vessel can lead to lower fuel consumption, resulting in significant cost savings for ship operators over the life of the vessel.

frp pipes and fittings for ship building

The versatility of FRP also allows for a wide range of applications within shipbuilding. FRP pipes and fittings can be used in various systems, including water systems, wastewater treatment, fuel systems, and ventilation. They can be molded into intricate shapes, accommodating the specific requirements of different designs and layouts, which is particularly advantageous in the often-complicated architecture of ships.

Additionally, FRP is non-conductive, offering electrical insulation that is beneficial in certain applications where electrical interference could be a concern. Its ability to withstand extreme temperatures and pressures further solidifies FRP’s role as a reliable material choice in shipbuilding.

In conclusion, the integration of FRP pipes and fittings in shipbuilding marks a significant advancement in maritime technology. With their corrosion resistance, lightweight properties, and versatility, FRP materials contribute to more durable and efficient vessels, thereby supporting the growing demands of modern maritime operations. As shipyards continue to innovate, the use of FRP is expected to become increasingly prevalent, shaping the future of the marine industry.