-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp pipes and fittings for ship building

FRP Pipes and Fittings for Shipbuilding

In the ever-evolving world of shipbuilding, the choice of materials plays a crucial role in determining the performance, longevity, and safety of maritime vessels. Among the various materials available, Fiber Reinforced Plastic (FRP) has emerged as a preferred option for pipes and fittings. This article explores the significance, benefits, and applications of FRP in shipbuilding, highlighting why it is becoming increasingly indispensable in modern marine construction.

The Nature of FRP

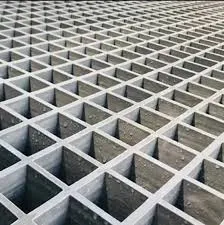

Fiber Reinforced Plastic is a composite material made of a polymer matrix reinforced with fibers. Typically, glass, carbon, or aramid fibers are used to enhance the strength and durability of plastics. This combination results in a material that possesses exceptional mechanical properties, chemical resistance, and low weight, making it particularly suitable for marine applications. The versatility of FRP allows it to be molded into various shapes, making it ideal for complex piping systems and fittings required in shipbuilding.

Advantages of FRP Pipes and Fittings

1. Corrosion Resistance One of the standout features of FRP is its outstanding resistance to corrosion. Marine environments expose materials to saltwater, moisture, and various chemicals that can rapidly decompose traditional materials like steel. FRP's inherent properties enable it to withstand these harsh conditions without succumbing to rust or degradation, ensuring a longer lifespan for ship components.

2. Lightweight Composition Compared to traditional materials such as steel and iron, FRP pipes and fittings are significantly lighter. This weight reduction is crucial in shipbuilding, as it enhances fuel efficiency and overall vessel performance. Lighter ships can achieve better speed and maneuverability, translating to lower operational costs over time.

3. Ease of Installation The lightweight nature of FRP materials not only simplifies handling but also reduces labor costs during installation. Additionally, FRP can be molded into any shape, allowing for custom fittings that align perfectly with the ship's design, minimizing the need for extensive modifications during installation.

frp pipes and fittings for ship building

4. Thermal Insulation FRP provides excellent thermal insulation properties. This quality helps in regulating temperature within the ship, contributing to energy efficiency and comfort for passengers and crew alike. The insulation properties also protect sensitive equipment from temperature fluctuations that may degrade performance.

5. Environmental Impact With the rising focus on sustainability, using FRP contributes positively to environmental conservation efforts. Its longevity reduces the frequency of replacements and repairs, thus minimizing waste. Furthermore, FRP can be manufactured with lesser energy compared to metals, making it a more eco-friendly option.

Applications in Shipbuilding

FRP pipes and fittings are utilized in various applications within the maritime sector. They are commonly found in wastewater treatment systems, cooling water systems, fuel lines, and ballast and bilge systems. Furthermore, FRP components are essential in composite structures like decks, hulls, and superstructures where weight savings are paramount.

The shipbuilding industry also utilizes FRP for designing specialized tanks for cargo, fuel, and water storage. These tanks benefit from the composite's corrosion resistance and lightweight properties, allowing for safer and more efficient storage solutions.

Conclusion

As the shipbuilding industry continues to advance, the demand for innovative materials that enhance performance and durability is on the rise. FRP pipes and fittings have demonstrated their superiority over traditional materials in various aspects essential to maritime construction. Their corrosion resistance, lightweight nature, ease of installation, and environmental benefits position FRP as a critical player in modern shipbuilding. As more manufacturers recognize these advantages, it is likely that FRP will continue to see expanded use in the industry, ultimately contributing to safer, more sustainable, and more efficient maritime vessels. The transition towards FRP represents not only a material choice but also a commitment to embracing the future of shipbuilding technologies.