-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp pipes and fittings utilized in ship construction

FRP Pipes and Fittings Utilized in Ship Construction

The maritime industry has always been at the forefront of adopting advanced materials and technologies to enhance the performance, durability, and efficiency of ships. Among these innovations, Fiber-Reinforced Polymer (FRP) pipes and fittings have emerged as a game-changing solution for ship construction. This article explores the benefits, applications, and future potential of FRP in the maritime sector.

Understanding FRP Materials

FRP is a composite material made from a polymer matrix reinforced with fibers, typically glass or carbon. The combination of these materials results in a lightweight yet incredibly strong product that can withstand harsh environmental conditions. The unique properties of FRP, including corrosion resistance, low thermal conductivity, and high tensile strength, make it particularly suitable for various applications in shipbuilding.

Advantages of FRP Pipes and Fittings

1. Corrosion Resistance One of the most significant advantages of FRP is its exceptional resistance to corrosion. Unlike traditional metal pipes, which can degrade over time due to exposure to seawater, FRP materials maintain their integrity, reducing maintenance costs and extending the lifespan of the ship.

2. Lightweight The reduced weight of FRP compared to metal alternatives contributes to overall ship efficiency. Lighter materials can improve fuel efficiency by decreasing the overall weight of the vessel, allowing for better performance and lower operational costs.

3. High Strength-to-Weight Ratio FRP has a remarkable strength-to-weight ratio, which means it can support significant loads while being considerably lighter than many traditional materials. This property is particularly advantageous in applications that require both strength and lightweight attributes.

4. Thermal Insulation FRP provides excellent thermal insulation, which can help in maintaining the temperature of liquids transported through the pipes. This is especially important for transporting chemicals and fuels that require stable temperature control.

5. Ease of Installation FRP pipes and fittings are easier to handle and install compared to heavier metal pipes. Their lightweight nature simplifies transportation and reduces labor costs during installation, which is a significant factor in large shipbuilding projects.

Applications in Ship Construction

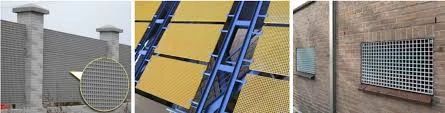

frp pipes and fittings utilized in ship construction

FRP pipes and fittings are increasingly being used in various applications across the marine sector. Some notable uses include

- Ballast Systems FRP pipes are often used in ballast systems to manage the ship’s weight distribution. Their corrosion resistance ensures the system remains efficient over time.

- Water and Wastewater Management These materials are ideal for piping systems that handle fresh water, gray water, and wastewater due to their non-corrosive nature and ability to withstand harsh chemicals.

- Fuel and Oil Transfer FRP pipes are used in fuel lines and oil transfer systems, where corrosion resistance is crucial to prevent leaks and ensure safety.

- Cooling Water Systems The thermal insulation properties of FRP make it suitable for cooling systems within the ship, ensuring efficiency and reliability.

Challenges and Considerations

Despite the numerous advantages, the adoption of FRP in shipbuilding does face challenges. For instance, while FRP materials can resist corrosion, they may be susceptible to impact damage, which requires careful consideration during design and installation. Additionally, the initial cost of FRP systems can be higher than traditional materials, though long-term savings can offset this expense.

The Future of FRP in Ship Construction

As the maritime industry continues to evolve, the demand for sustainable and efficient materials will likely drive further innovation in FRP technology. Research and development are focused on enhancing the durability and performance of FRP materials. Integrating smart technologies into FRP systems could also lead to improvements in monitoring and maintenance practices, further enhancing their viability.

Conclusion

In conclusion, FRP pipes and fittings represent a significant advancement in ship construction, offering a blend of durability, efficiency, and cost-effectiveness. With increasing emphasis on sustainability and performance, it is clear that FRP will play a vital role in the future of maritime engineering. As the industry embraces these innovative materials, we can expect to see continued improvements in ship safety, performance, and environmental impact.