-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding the Benefits and Applications of FRP Piping Systems in Modern Industries

Understanding FRP Piping Systems Advantages and Applications

Fiber Reinforced Plastic (FRP) piping systems have emerged as a vital component in various industries due to their unique properties and advantages. Made from a composite of resin and reinforcing fibers, FRP offers a lightweight, durable, and corrosion-resistant solution for transporting fluids. In this article, we delve into the characteristics, benefits, and applications of FRP piping systems, highlighting why they are increasingly favored over traditional materials like steel and concrete.

Composition and Properties of FRP Piping

FRP piping is composed of a base resin, which acts as a matrix, reinforced by fibers such as glass, carbon, or aramid. The choice of fiber significantly influences strength, stiffness, and resistance to chemicals. Commonly used resins include polyester, vinyl ester, and epoxy, each offering distinct benefits based on environmental conditions and the type of fluids being transported.

One of the standout properties of FRP pipes is their exceptional corrosion resistance. Unlike metal pipes that may rust or corrode upon exposure to certain chemicals or saline environments, FRP pipes remain unaffected, making them ideal for industries dealing with aggressive fluids. Moreover, their lightweight nature facilitates ease of handling and installation, reducing labor costs and time.

Advantages of FRP Piping Systems

1. Corrosion Resistance As mentioned, FRP piping offers outstanding resistance to chemicals, making it suitable for use in wastewater treatment, chemical processing, and oil and gas applications. This property helps extend the life of the piping system and reduce maintenance costs.

2. Lightweight Compared to traditional materials, FRP pipes are significantly lighter, allowing for easier transportation and installation. This can lead to reduced foundation requirements and lower shipping costs.

3. High Strength-to-Weight Ratio The reinforcement fibers provide substantial strength while maintaining lightweight characteristics, making FRP pipes highly effective in high-pressure applications.

4. Thermal Insulation FRP does not conduct heat, making it an effective insulator. This minimizes heat loss and reduces energy costs in systems that require temperature control.

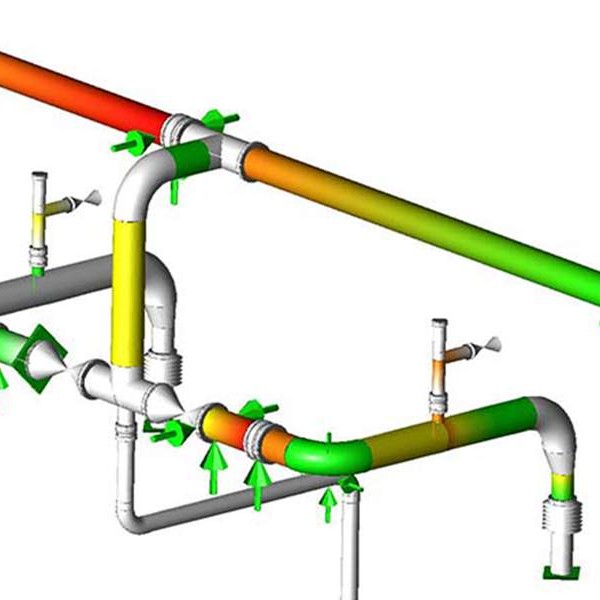

frp piping system

5. Flexibility in Design FRP can be molded into various shapes and sizes, allowing for greater design flexibility in construction and installation, which can be particularly beneficial in complex projects.

6. Sustainability As industries strive for greener solutions, FRP pipes can contribute to sustainable practices. They are recyclable, and many manufacturers are now producing them from recycled materials.

Applications of FRP Piping Systems

FRP piping systems find application in numerous industries, notably

- Water Treatment In municipal and industrial water treatment facilities, FRP pipes transport corrosive chemicals such as chlorine and sulfuric acid without fear of degradation. - Chemical Processing The chemical industry relies on FRP for handling aggressive chemicals, facilitating safe and efficient processing.

- Oil and Gas In the oil and gas sector, FRP pipes are used for transporting crude oil, natural gas, and their derivatives, especially where conventional materials may suffer from corrosion.

- Mining FRP piping is utilized in mining operations to handle slurries and chemicals used in mineral processing.

- Marine Applications Due to their corrosion resistance, FRP pipes are suitable for offshore platforms and coastal infrastructures, where exposure to saltwater is a concern.

Conclusion

In conclusion, FRP piping systems offer an innovative solution to various industrial challenges, combining durability, efficiency, and versatility. With their many advantages over traditional piping materials, FRP systems are poised to play a pivotal role in the future of fluid transport across multiple sectors. As industries continue to evolve, investing in advanced materials like FRP will undeniably pave the way for more resilient and sustainable operations.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025