-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 05:59

Back to list

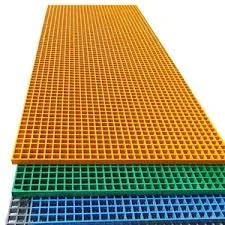

frp playground equipment

Fiberglass Reinforced Plastic (FRP) playground equipment is revolutionizing the world of outdoor play. Favored for its exceptional durability, environmental sustainability, and superior safety features, FRP stands at the frontline of innovative playground manufacturing. As an expert in playground equipment development, the exploration into FRP's applications offers a wealth of insights into how it enhances both the play experience and operational longevity.

Design flexibility is another compelling advantage of FRP playground equipment. The material can be molded into various shapes and combinations, accommodating creative designs that captivate children’s imagination and encourage interactive play. Whether creating innovative climbing structures or whimsical slides, designers have the freedom to push the boundaries of traditional playground aesthetics and functionalities. This versatility not only enhances the aesthetic quality of public spaces but also presents opportunities to tailor play equipment to specific community needs or thematic ventures. The integration of FRP in playground equipment aligns well with current trends in urban design that emphasize inclusive and adaptive play spaces. Given its adaptable nature, FRP can be used to develop equipment that meets diverse accessibility standards, ensuring children of different ability levels can participate in play. This inclusivity is vital in fostering social interaction and development among children, promoting a sense of community and belonging. For those overseeing playground projects, choosing FRP equipment backed by thorough manufacturers’ guarantees and quality certifications further enhances its trustworthiness and reliability. Partnering with seasoned suppliers familiar with safety standards and requirements ensures that municipalities, schools, and private sectors alike can deploy playgrounds that not only engage children but stand the scrutiny of safety audits and inspections. Ultimately, the decision to embrace FRP playground equipment is a commitment to superior quality and social responsibility—one that supports safe, sustainable, and creatively enriching environments for the community's youth. Investing in FRP materials means investing in a future where innovation and environmental stewardship go hand in hand, paving the way for playgrounds where generations of children can fulfill their play potential.

Design flexibility is another compelling advantage of FRP playground equipment. The material can be molded into various shapes and combinations, accommodating creative designs that captivate children’s imagination and encourage interactive play. Whether creating innovative climbing structures or whimsical slides, designers have the freedom to push the boundaries of traditional playground aesthetics and functionalities. This versatility not only enhances the aesthetic quality of public spaces but also presents opportunities to tailor play equipment to specific community needs or thematic ventures. The integration of FRP in playground equipment aligns well with current trends in urban design that emphasize inclusive and adaptive play spaces. Given its adaptable nature, FRP can be used to develop equipment that meets diverse accessibility standards, ensuring children of different ability levels can participate in play. This inclusivity is vital in fostering social interaction and development among children, promoting a sense of community and belonging. For those overseeing playground projects, choosing FRP equipment backed by thorough manufacturers’ guarantees and quality certifications further enhances its trustworthiness and reliability. Partnering with seasoned suppliers familiar with safety standards and requirements ensures that municipalities, schools, and private sectors alike can deploy playgrounds that not only engage children but stand the scrutiny of safety audits and inspections. Ultimately, the decision to embrace FRP playground equipment is a commitment to superior quality and social responsibility—one that supports safe, sustainable, and creatively enriching environments for the community's youth. Investing in FRP materials means investing in a future where innovation and environmental stewardship go hand in hand, paving the way for playgrounds where generations of children can fulfill their play potential.

Next:

Related Products