-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

FRP Solutions for Enhancing Thermal and Nuclear Power Efficiency and Safety

FRP Products for Thermal and Nuclear Power Enhancing Efficiency and Safety

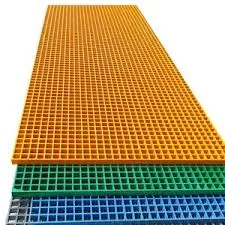

Fiber Reinforced Polymer (FRP) products have become increasingly vital in the thermal and nuclear power sectors, owing to their unique properties that combine strength, durability, and resistance to harsh environmental conditions. As power plants seek to improve operational efficiency while ensuring safety and reducing maintenance costs, the integration of FRP materials into various components has proven to be a game-changer.

Properties of FRP

FRP materials consist of a polymer matrix reinforced with fibrous components such as carbon, glass, or aramid fibers. This combination results in a lightweight material with high tensile strength and excellent resistance to corrosion and temperature variations. Particularly in thermal and nuclear power environments, where structural integrity is paramount due to exposure to high temperatures, radiation, and aggressive chemicals, FRP products offer several advantages over traditional materials such as steel and concrete.

Applications in Thermal Power

In thermal power plants, FRP products are utilized in various applications, including piping systems, cooling towers, and structural components. The resistance of FRP to corrosive substances makes it an ideal choice for piping systems that transport hot water and steam. Unlike traditional metal pipes, which can suffer from rust and corrosion, FRP pipes maintain their integrity over time, resulting in lower maintenance costs and fewer shutdowns for repairs.

Cooling towers, critical in dissipating excess heat from thermal power generation processes, also benefit from FRP products. The lightweight nature of FRP allows for easier installation and reduces the load on support structures. Moreover, FRP’s resistance to water and chemical exposure ensures longevity and reliability in cooling tower applications.

Advancements in Nuclear Power

frp products for thermal and nuclear power

In the nuclear power sector, where safety and reliability are of utmost importance, the deployment of FRP products has been transformative. The materials are employed in various applications, including reactor containment vessels, radiation shielding, and structural reinforcements. FRP’s ability to withstand radiation exposure without significant degradation enhances the safety and lifespan of these critical components.

One of the significant advantages of FRP in nuclear applications is its non-conductive nature. This property helps minimize the risk of electrical interference, which is crucial in environments with sensitive electronic equipment. Additionally, the lightweight characteristics of FRP allow for the creation of more efficient designs, reducing the overall weight of structures and simplifying installation processes.

Future Prospects and Innovations

As the demand for sustainable energy sources grows, the role of FRP in power generation will likely continue to expand. Researchers are actively exploring advanced FRP composites that integrate smart technologies, such as sensors for real-time monitoring of structural health. This innovation could enhance maintenance practices and ensure that any potential issues are addressed before they escalate into significant problems.

Furthermore, the ongoing development of more environmentally friendly resins shows promise for bolstering the sustainability of FRP products. By reducing the environmental impact associated with the manufacturing and disposal of these materials, the power generation industry can make strides toward greener practices.

Conclusion

In conclusion, FRP products are revolutionizing the thermal and nuclear power industries by offering innovative solutions that improve efficiency, safety, and sustainability. As power plants continue to evolve and adapt to the demands of modern energy production, the integration of advanced FRP materials will play a crucial role in ensuring the reliability and longevity of power generation systems, ultimately contributing to a more sustainable energy future. The ongoing research and development in this field promise exciting advancements, ushering in a new era of performance and resilience in power generation.