-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

FRP Solutions for Thermal and Nuclear Power Applications and Innovations

FRP Products for Thermal and Nuclear Power Generation

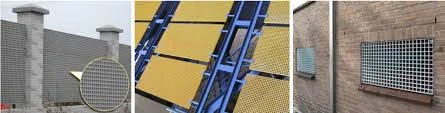

Fiber-Reinforced Polymer (FRP) materials have garnered significant attention in the field of power generation, particularly in thermal and nuclear power systems. These advanced composite materials are composed of a polymer matrix reinforced with fibers, typically glass or carbon, which provides exceptional strength, durability, and resistance to corrosion. The unique properties of FRP make it an ideal choice for various applications in power plants, enhancing both performance and efficiency.

FRP Products for Thermal and Nuclear Power Generation

Corrosion resistance is another significant benefit of FRP products. Traditional materials like carbon steel and aluminum are prone to corrosion, especially in the moist environments typical of thermal power plants and the unique conditions found in nuclear reactors. The use of FRP reduces maintenance costs and extends the lifespan of infrastructure by ensuring that components such as cooling towers, storage tanks, and piping systems remain intact under harsh operating conditions. With a longer service life, utilities can reduce replacement frequency, ultimately lowering operational costs.

frp products for thermal and nuclear power

Moreover, FRP materials are designed to withstand extreme temperatures and pressures, making them suitable for thermal and nuclear applications. In thermal power plants, where high temperatures are the norm, the thermal stability of FRP ensures that components perform reliably. In nuclear plants, where safety is vital, FRP's ability to maintain structural integrity under various conditions is invaluable, playing a crucial role in both safety and efficiency.

The versatility of FRP allows for custom designs tailored to specific applications. For example, fire-resistant FRP composites can be utilized in nuclear plant containment areas, ensuring compliance with safety regulations. Additionally, FRP's adaptability enables manufacturers to create complex shapes and configurations that optimize system performance and reduce energy loss.

In conclusion, FRP products present a compelling solution for the challenges faced in thermal and nuclear power generation. Their lightweight nature, corrosion resistance, thermal stability, and design flexibility make them essential materials for modern power infrastructure. As the energy sector continues to evolve, the adoption of advanced materials like FRP will be crucial in enhancing operational efficiency, safety, and sustainability. Embracing these innovative solutions will not only facilitate the ongoing transition to cleaner energy production but also ensure the long-term viability of power generation systems worldwide.