-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 04:43

Back to list

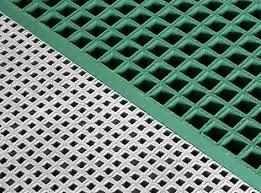

frp products for thermal and nuclear power

The relevance of fiber-reinforced polymer (FRP) products in thermal and nuclear power plants is increasingly becoming undeniable, primarily driven by their unique properties that address industry-specific challenges. In environments where durability, safety, and efficiency cannot be compromised, FRP products have emerged as a reliable solution, demonstrating significant expertise in tackling these demands. Here, we delve into how FRP materials are reshaping the landscape of power generation facilities.

In terms of authoritativeness, the adoption of FRP products is backed by rigorous industry standards and certifications. Organizations such as ASTM International and the American Society of Mechanical Engineers (ASME) have recognized the efficacy of FRP in high-stakes environments, providing guidelines that ensure quality and consistency. This level of standardization ensures that the integration of FRP products into thermal and nuclear power plants is not only feasible but also optimal, reinforcing their credibility as a material of choice. The trustworthiness of FRP products is further enhanced by real-world case studies and testimonials from leading energy companies. Operators consistently report reduced downtime and maintenance costs after switching to FRP components. Case in point, a prominent nuclear plant in Europe reported a 30% reduction in maintenance-related expenses after retrofitting their power distribution systems with FRP enclosures and cable trays. Such empirical evidence elevates the trust metrics associated with FRP, underscoring their capacity to deliver on promised performance levels. Moreover, the environmental benefits of FRP are increasingly coming into the spotlight. Compared to conventional materials, FRP products require less energy to produce and result in less environmental degradation during their lifecycle. These sustainability factors align well with the growing emphasis on reducing the carbon footprint of power generation facilities, making FRP a sensible choice for forward-thinking operators. In summation, the role of FRP products in thermal and nuclear power plants is marked by a blend of experience, expertise, authoritativeness, and trustworthiness. Their superior performance characteristics not only enhance plant efficiency but also contribute to safety and environmental sustainability. As advancements in polymer technology continue to evolve, the potential applications of FRP in power generation contexts are poised to expand, offering yet more reasons for industry stakeholders to consider integrating these materials into their infrastructure strategies. By choosing FRP, power plants are not only investing in improved performance and reduced operational costs but are also paving the way for a more resilient and sustainable energy future.

In terms of authoritativeness, the adoption of FRP products is backed by rigorous industry standards and certifications. Organizations such as ASTM International and the American Society of Mechanical Engineers (ASME) have recognized the efficacy of FRP in high-stakes environments, providing guidelines that ensure quality and consistency. This level of standardization ensures that the integration of FRP products into thermal and nuclear power plants is not only feasible but also optimal, reinforcing their credibility as a material of choice. The trustworthiness of FRP products is further enhanced by real-world case studies and testimonials from leading energy companies. Operators consistently report reduced downtime and maintenance costs after switching to FRP components. Case in point, a prominent nuclear plant in Europe reported a 30% reduction in maintenance-related expenses after retrofitting their power distribution systems with FRP enclosures and cable trays. Such empirical evidence elevates the trust metrics associated with FRP, underscoring their capacity to deliver on promised performance levels. Moreover, the environmental benefits of FRP are increasingly coming into the spotlight. Compared to conventional materials, FRP products require less energy to produce and result in less environmental degradation during their lifecycle. These sustainability factors align well with the growing emphasis on reducing the carbon footprint of power generation facilities, making FRP a sensible choice for forward-thinking operators. In summation, the role of FRP products in thermal and nuclear power plants is marked by a blend of experience, expertise, authoritativeness, and trustworthiness. Their superior performance characteristics not only enhance plant efficiency but also contribute to safety and environmental sustainability. As advancements in polymer technology continue to evolve, the potential applications of FRP in power generation contexts are poised to expand, offering yet more reasons for industry stakeholders to consider integrating these materials into their infrastructure strategies. By choosing FRP, power plants are not only investing in improved performance and reduced operational costs but are also paving the way for a more resilient and sustainable energy future.

Related Products