-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 29, 2025 01:49

Back to list

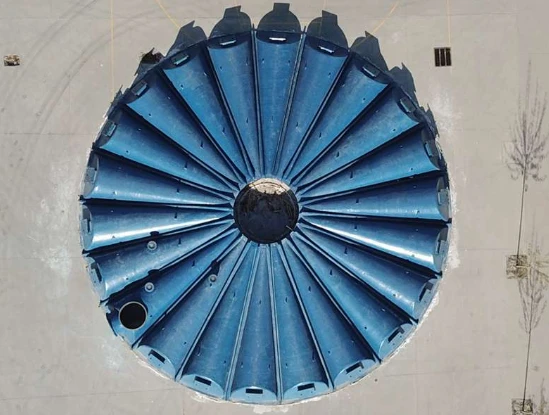

frp rectangular tank

Fiberglass Reinforced Plastic (FRP) rectangular tanks have become pivotal in industries ranging from chemical processing to aquaculture, owing to their robustness, adaptability, and cost-efficiency. They are seen as an excellent alternative to traditional materials due to their lightweight nature, corrosion resistance, and long service life.

Aquaculture has also benefited from the integration of FRP tanks. Their smooth surfaces make them ideal for rearing sensitive fish species, preventing injury and disease proliferation. Additionally, FRP tanks are less likely to leach harmful compounds into the water, ensuring a healthier breeding environment for aquatic life. The tanks' thermal insulating properties help maintain a stable water temperature, conducive to optimal growth and reproduction of fish. For companies focused on sustainability, the ecological footprint of FRP rectangular tanks is highly appealing. Their longevity reduces the frequency of replacements, thus conserving resources. Furthermore, when these tanks reach the end of their service life, their components can often be recycled or repurposed, aligning with the global shift toward more sustainable industrial practices. The versatility of FRP rectangular tanks also extends to the food and beverage industry. With strict hygiene requirements, facilities need storage solutions that can be thoroughly sanitized without degrading over time. FRP tanks meet these needs, being non-porous and resistant to frequent cleaning chemicals and processes. Trustworthiness in the market for FRP tanks is elevated when manufacturers adhere to international standards such as ASTM and ISO certifications. These standards ensure that tanks meet stringent safety and performance criteria, rendering them reliable. Consumers are advised to seek suppliers who transparently offer these assurances, backed by comprehensive warranties, as such actions amplify consumer confidence in the product. Through years of innovation and practical implementation, FRP rectangular tanks have established themselves as a staple in industrial storage solutions. Their technical and environmental advantages over traditional materials underscore their significance in modern engineering. As industries continue to evolve, the adaptability and resilience of FRP tanks will undoubtedly secure their place in helping businesses meet both their operational and sustainability goals.

Aquaculture has also benefited from the integration of FRP tanks. Their smooth surfaces make them ideal for rearing sensitive fish species, preventing injury and disease proliferation. Additionally, FRP tanks are less likely to leach harmful compounds into the water, ensuring a healthier breeding environment for aquatic life. The tanks' thermal insulating properties help maintain a stable water temperature, conducive to optimal growth and reproduction of fish. For companies focused on sustainability, the ecological footprint of FRP rectangular tanks is highly appealing. Their longevity reduces the frequency of replacements, thus conserving resources. Furthermore, when these tanks reach the end of their service life, their components can often be recycled or repurposed, aligning with the global shift toward more sustainable industrial practices. The versatility of FRP rectangular tanks also extends to the food and beverage industry. With strict hygiene requirements, facilities need storage solutions that can be thoroughly sanitized without degrading over time. FRP tanks meet these needs, being non-porous and resistant to frequent cleaning chemicals and processes. Trustworthiness in the market for FRP tanks is elevated when manufacturers adhere to international standards such as ASTM and ISO certifications. These standards ensure that tanks meet stringent safety and performance criteria, rendering them reliable. Consumers are advised to seek suppliers who transparently offer these assurances, backed by comprehensive warranties, as such actions amplify consumer confidence in the product. Through years of innovation and practical implementation, FRP rectangular tanks have established themselves as a staple in industrial storage solutions. Their technical and environmental advantages over traditional materials underscore their significance in modern engineering. As industries continue to evolve, the adaptability and resilience of FRP tanks will undoubtedly secure their place in helping businesses meet both their operational and sustainability goals.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025