-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Innovative Applications of FRP Rectangular Tubes in Modern Construction and Engineering

Understanding FRP Rectangular Tubes Applications and Advantages

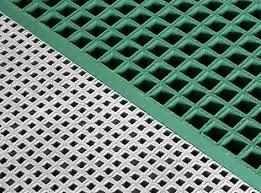

Fiber Reinforced Polymer (FRP) rectangular tubes are increasingly gaining popularity in various industries due to their unique combination of strength, lightness, and durability. Unlike traditional materials, FRP, which consists of a polymer matrix reinforced with fibers, offers excellent mechanical properties and corrosion resistance. This article delves into the characteristics, advantages, and applications of FRP rectangular tubes.

What are FRP Rectangular Tubes?

FRP rectangular tubes are structural components manufactured by combining composite materials that include a resin matrix and reinforcing fibers such as glass, carbon, or aramid. These tubes are formed into a rectangular shape, providing efficient structural support while also being lightweight. The manufacturing process often involves techniques such as pultrusion or filament winding, which allow for precise control over the tube's characteristics and dimensions.

Key Advantages of FRP Rectangular Tubes

1. Light Weight One of the standout features of FRP rectangular tubes is their low weight compared to traditional materials like steel and aluminum. This property makes them easier to handle and install, reducing labor costs and time on construction sites.

2. Excellent Corrosion Resistance FRP materials exhibit high resistance to corrosive environments, which makes them ideal for applications in chemical processing, marine environments, and infrastructure exposed to harsh weather conditions. This characteristic significantly extends their lifespan and reduces maintenance costs.

3. High Strength-to-Weight Ratio While being incredibly light, FRP rectangular tubes do not compromise on strength. Their high strength-to-weight ratio makes them suitable for structural applications where load-bearing capacity is essential without adding excessive weight.

4. Design Flexibility These tubes can be manufactured in various sizes and configurations, allowing for greater design flexibility. Engineers can easily customize dimensions and properties to meet specific project requirements, making them versatile solutions in construction and manufacturing.

5. Thermal and Electrical Insulation Unlike metals, FRP materials do not conduct electricity and provide good thermal insulation. This property is advantageous in applications where electrical safety and temperature control are important.

frp rectangular tube

Applications of FRP Rectangular Tubes

Given their unique properties, FRP rectangular tubes find applications across numerous sectors

- Construction and Infrastructure In the construction industry, FRP tubes are used in beams, columns, and trusses. They are also employed in bridge construction to reduce the weight of the structure without sacrificing load-bearing capacity.

- Transportation The lightweight nature of FRP tubes is beneficial in the transportation sector, particularly in vehicles, where every kilogram counts. These tubes help manufacturers produce lighter vehicles that enhance fuel efficiency and reduce emissions.

- Marine Applications Due to their corrosion resistance, FRP rectangular tubes are widely used in marine structures such as docks, pontoons, and boat components. Their durability ensures longevity and reliability in harsh marine environments.

- Utility and Telecom FRP tubes are used in utility poles and telecommunications infrastructure. Their lightweight and non-conductive properties make them a preferred choice for above-ground installations.

- Sports and Recreation In the sports industry, FRP tubes are used in the manufacture of various equipment, such as fishing rods, bicycle frames, and playground structures, benefiting from their strength and lightweight characteristics.

Conclusion

FRP rectangular tubes present a compelling option for a wide range of applications thanks to their unique blend of properties. Their light weight, high strength, corrosion resistance, and design flexibility make them invaluable in modern engineering and construction projects. As industries continue to aim for more efficient and sustainable materials, FRP rectangular tubes are expected to play a crucial role in the future of structural design and their applications are likely to expand, supporting innovative advancements across multiple sectors.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025