-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp rectangular tube

Understanding FRP Rectangular Tubes Applications and Advantages

Fiber Reinforced Polymer (FRP) materials have revolutionized various engineering fields, particularly in structural applications. Among the various shapes used, FRP rectangular tubes stand out due to their unique combination of high strength, lightweight, and corrosion resistance. This article delves into the characteristics, advantages, and applications of FRP rectangular tubes.

What is FRP?

FRP is a composite material made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The combination of these materials offers superior mechanical properties compared to traditional materials like steel and aluminum. FRP materials are known for their ability to withstand harsh environmental conditions, making them ideal for a variety of structural applications.

Characteristics of FRP Rectangular Tubes

FRP rectangular tubes are characterized by their geometric shape and the reinforcement structure that enhances their mechanical properties. The flat surfaces of rectangular tubes allow for easy integration into various architectural designs and structural frameworks, making them a popular choice in construction and manufacturing.

1. High Strength-to-Weight Ratio One of the most significant advantages of FRP rectangular tubes is their exceptional strength-to-weight ratio. This allows engineers to design lighter structures without compromising strength, which is especially important in applications where weight savings are critical, such as in aerospace and automotive industries.

2. Corrosion Resistance Unlike traditional metal structures that are prone to rust and corrosion, FRP materials are highly resistant to chemical degradation. This property makes FRP rectangular tubes ideal for use in environments that are corrosive, such as marine applications or chemical processing industries.

3. Thermal Insulation FRP composite materials offer better thermal insulation compared to metals. This is beneficial in applications where temperature control is crucial, helping to maintain optimal conditions within structures or equipment.

4. Versatile Design Options The manufacturing process of FRP allows for versatility in design. Engineers can achieve various shapes and sizes according to specific project requirements. The available colors and surface finishes can also enhance the aesthetic appeal of structures.

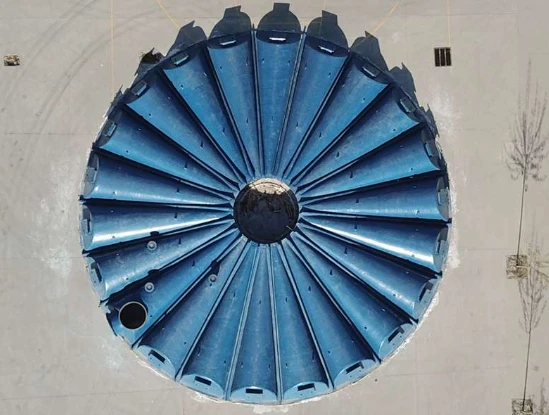

frp rectangular tube

Applications of FRP Rectangular Tubes

The applications of FRP rectangular tubes span across various industries, reflecting their versatility and reliability.

1. Construction and Infrastructure In civil engineering, FRP rectangular tubes are used for beams, columns, and other structural components. Their lightweight nature helps reduce transportation costs and makes the installation process more efficient. Additionally, they are utilized in bridges and walkways where corrosion resistance is essential.

2. Aerospace and Automotive Due to their lightweight and high-strength properties, FRP rectangular tubes are increasingly being used in the aerospace and automotive industries. They contribute to fuel efficiency and enhance overall performance by reducing the weight of components without sacrificing safety.

3. Marine Applications The marine environment poses significant challenges due to saltwater and humidity. FRP rectangular tubes are utilized in the construction of docks, boats, and other watercraft components, where their corrosion resistance is invaluable.

4. Sports Equipment The lightweight and strong characteristics of FRP materials have led to their use in sporting equipment, such as racquets, bicycles, and other athletic gear, allowing for enhanced performance.

5. Industrial Applications Beyond construction and consumer goods, FRP rectangular tubes find their use in manufacturing equipment, chemical processing systems, and electrical enclosures, proving essential in industrial settings where durability and resistance to harsh conditions are critical.

Conclusion

FRP rectangular tubes represent a significant advancement in material science and engineering. Their unique properties, such as high strength-to-weight ratio, corrosion resistance, and versatile design options, make them suitable for a wide range of applications. As industries continue to seek materials that offer efficiency and durability, FRP rectangular tubes are poised to play a pivotal role in the future of construction, transportation, and manufacturing. With ongoing advancements in FRP technology, we can expect even broader applications and improved performance characteristics in the years to come.