-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 20, 2025 13:45

Back to list

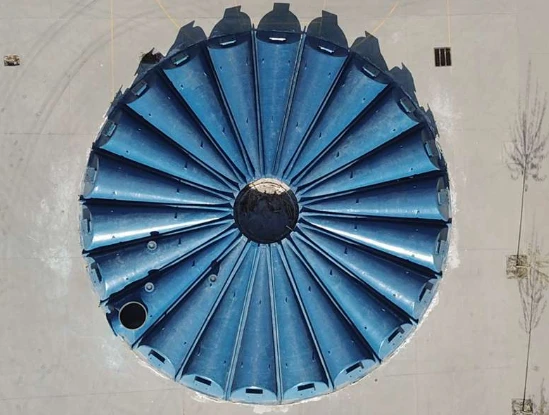

Winding Machines for Pipes & Tanks

FRP sand pipes, distinguished by their amalgamation of fiberglass reinforced plastic with a sand-filled core, are revolutionizing the piping industry. Offering a unique blend of strength, corrosion resistance, and sustainability, these pipes are drawing attention from industry professionals seeking high-performance products for diverse applications.

Projects that have implemented FRP sand pipes report notable improvements in operational efficiency. A case study from a chemical processing plant showed a 30% decrease in maintenance costs after switching to FRP piping systems. These savings, coupled with the pipes' durability, underline their cost-effectiveness over time—an essential consideration for long-term infrastructure investments. The expertise behind designing and creating FRP sand pipes demands attention. Engineers specialized in composites work meticulously to refine the balance between fiber, resin, and sand distributions. Continuous innovation in resin formulations enhances the thermal and mechanical properties of the pipes, accommodating varying industrial needs. Professionals emphasize the importance of adhering to international standards, including ASTM and ISO, ensuring quality and performance across all installations. Furthermore, authoritativeness in adopting FRP sand pipes is supported by certifications and rigorous testing processes. Organizations endorse these pipes after exhaustive assessments involving pressure, durability, and environmental impact tests. Such stringent evaluations assure stakeholders of the piping system's reliability and long-term functionality. Trustworthiness is naturally woven into the narrative of FRP sand pipes through proven field outcomes and customer testimonials. End-users express confidence in the reliability of these systems, often highlighted through independent reviews and client endorsements. Reputable manufacturers facilitate transparency by providing detailed material specifications and performance warranties, reinforcing trust among consumers and industry experts alike. In conclusion, FRP sand pipes emerge as a leading solution in the transition towards more sustainable and resilient infrastructure. Their advantageous features, including superior strength, corrosion resistance, and eco-friendliness, combined with verified field success, position them as viable alternatives to traditional piping systems. Industry professionals advocating for their use highlight the comprehensive benefits and sustained ROI (return on investment), attesting to the pipes' enduring value in modern infrastructure development. As the push for innovative, sustainable engineering solutions continues, FRP sand pipes undoubtedly stand at the forefront, setting new benchmarks for performance and reliability in fluid transport systems.

Projects that have implemented FRP sand pipes report notable improvements in operational efficiency. A case study from a chemical processing plant showed a 30% decrease in maintenance costs after switching to FRP piping systems. These savings, coupled with the pipes' durability, underline their cost-effectiveness over time—an essential consideration for long-term infrastructure investments. The expertise behind designing and creating FRP sand pipes demands attention. Engineers specialized in composites work meticulously to refine the balance between fiber, resin, and sand distributions. Continuous innovation in resin formulations enhances the thermal and mechanical properties of the pipes, accommodating varying industrial needs. Professionals emphasize the importance of adhering to international standards, including ASTM and ISO, ensuring quality and performance across all installations. Furthermore, authoritativeness in adopting FRP sand pipes is supported by certifications and rigorous testing processes. Organizations endorse these pipes after exhaustive assessments involving pressure, durability, and environmental impact tests. Such stringent evaluations assure stakeholders of the piping system's reliability and long-term functionality. Trustworthiness is naturally woven into the narrative of FRP sand pipes through proven field outcomes and customer testimonials. End-users express confidence in the reliability of these systems, often highlighted through independent reviews and client endorsements. Reputable manufacturers facilitate transparency by providing detailed material specifications and performance warranties, reinforcing trust among consumers and industry experts alike. In conclusion, FRP sand pipes emerge as a leading solution in the transition towards more sustainable and resilient infrastructure. Their advantageous features, including superior strength, corrosion resistance, and eco-friendliness, combined with verified field success, position them as viable alternatives to traditional piping systems. Industry professionals advocating for their use highlight the comprehensive benefits and sustained ROI (return on investment), attesting to the pipes' enduring value in modern infrastructure development. As the push for innovative, sustainable engineering solutions continues, FRP sand pipes undoubtedly stand at the forefront, setting new benchmarks for performance and reliability in fluid transport systems.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025