-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

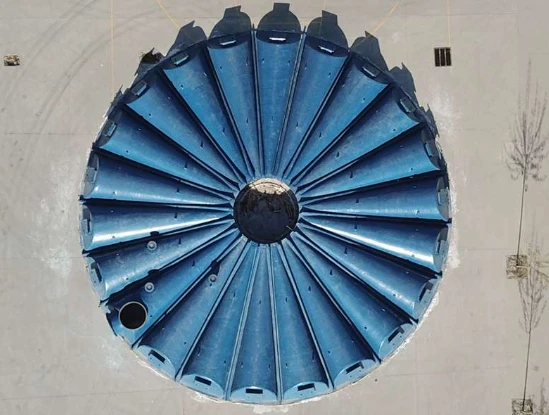

Innovative Solutions for Efficient Air Filtration Using FRP Scrubber Technology

Understanding FRP Scrubbers A Key Component in Emission Control

In recent years, environmental regulations and the need for sustainable industrial practices have led to the development and implementation of various technologies aimed at reducing emissions. One such technology is the Fiberglass Reinforced Plastic (FRP) scrubber, which plays a vital role in controlling air pollution. This article delves into the features, advantages, and applications of FRP scrubbers, highlighting their importance in modern industrial processes.

What is an FRP Scrubber?

FRP scrubbers are advanced air pollution control systems designed to remove harmful pollutants from industrial exhaust gases. Constructed from fiberglass reinforced plastic, these scrubbers are lightweight, durable, and resistant to corrosive chemicals, making them ideal for handling various gaseous emissions. The primary function of an FRP scrubber is to absorb and neutralize toxic substances from air streams, including volatile organic compounds (VOCs), sulfur dioxide (SO2), ammonia (NH3), and particulate matter.

How Do FRP Scrubbers Work?

The operational principle of FRP scrubbers is based on the concept of gas-liquid contact. The process typically involves the following steps

1. Gas Inlet Polluted gas enters the scrubber through an inlet system. 2. Scrubbing Media Once inside, the gas comes into contact with a scrubbing liquid, usually a water-based solution mixed with chemicals designed to react with the pollutants. 3. Absorption and Chemical Reaction As the dirty gas bubbles through the scrubbing liquid, harmful components are absorbed or react chemically. This happens in both counterflow or crossflow arrangements, depending on the scrubber design. 4. Gas Outlet After passing through the scrubber, the cleaned gas is released into the atmosphere, significantly reducing its pollutant content. 5. Sludge Removal The contaminants accumulate in the scrubbing liquid and must be periodically removed and disposed of, often in the form of sludge.

Advantages of FRP Scrubbers

1. Corrosion Resistance One of the major advantages of FRP scrubbers is their high resistance to corrosive substances. Unlike traditional materials such as metal, FRP does not rust, ensuring longevity and reducing maintenance costs.

frp scrubber

2. Lightweight and Easy Installation The lightweight nature of fiberglass allows for easier transportation and installation, which can save time and labor costs during setup.

3. Versatility FRP scrubbers can be designed to handle various gases and can be customized to meet specific industry needs. This versatility makes them suitable for diverse sectors, including chemical manufacturing, food processing, and wastewater treatment.

4. Efficiency These scrubbers can achieve high removal efficiencies for a wide range of pollutants, making them effective tools for meeting stringent environmental regulations.

5. Cost-Effectiveness Although the initial investment in FRP scrubbers may be higher than other materials, the long-term savings on maintenance, durability, and energy efficiency can offset the costs significantly.

Applications of FRP Scrubbers

FRP scrubbers are widely used across different industries. Some notable applications include

- Chemical Processing Industries that produce chemicals often generate harmful emissions that can be effectively treated using FRP scrubbers. - Wastewater Treatment Plants These facilities utilize scrubbers to control odors and remove harmful gases released during the treatment process. - Food and Beverage Industry During production, various gases are emitted, and scrubbers help in minimizing the environmental impact. - Pharmaceuticals In the pharmaceutical sector, strict regulations on emissions necessitate the use of efficient scrubbing systems.

Conclusion

As industries continue to face increasing scrutiny regarding their environmental impact, technologies like FRP scrubbers are becoming essential tools for ensuring compliance with air quality regulations. Their durability, efficiency, and adaptability make them an excellent choice for a wide range of applications, positioning them as a vital component in the effort to combat air pollution. As we move towards a more sustainable future, investing in advanced emission control technologies like FRP scrubbers will undoubtedly play a crucial role in fostering a cleaner and healthier environment for generations to come.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025