-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 09, 2025 12:30

Back to list

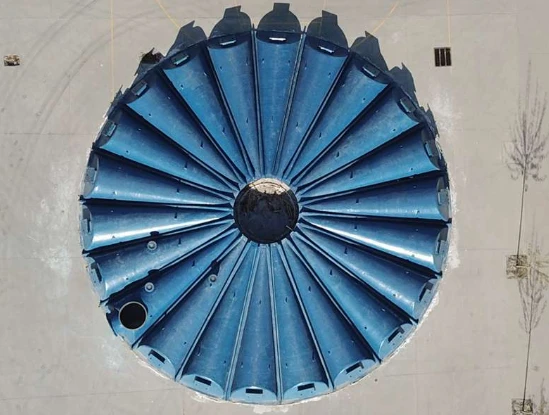

frp scrubber

FRP scrubbers, an essential component in industrial applications, are at the forefront of air pollution control technologies. Craftsmen and engineers alike appreciate their efficiency and durability. My extensive experience with these systems has revealed their transformative impact on maintaining air quality standards across various industries.

Trustworthiness is another key component in the decision-making process for industrial clients. Manufacturers of FRP scrubbers are often certified and adhere to international quality standards, ensuring that these scrubbers can be trusted to perform under pressure. High-profile case studies and endorsements from leading industrial players provide further assurance of their reliability and effectiveness. Furthermore, investing in an FRP scrubber showcases a commitment to sustainability and corporate social responsibility. By implementing such advanced pollution control equipment, companies not only comply with environmental regulations but also demonstrate leadership in protecting the environment, thus enhancing their corporate image and trustworthiness among consumers and stakeholders. In summary, FRP scrubbers are indispensable for industries committed to robust air pollution control strategies. With notable advantages in durability, efficiency, and cost-effectiveness, they provide a comprehensive solution to modern environmental challenges. Their proven track record of performance and compliance, underpinned by expert engineering and rigorous standards, solidifies their authority in the market. For those considering an investment in air pollution control technology, FRP scrubbers represent a prudent choice rooted in both practicality and a forward-thinking approach to sustainability. My extensive involvement with these systems affirms that the strategic integration of an FRP scrubber into existing operations can yield significant benefits, aligning operational goals with environmental stewardship. As the demand for cleaner industrial processes escalates, the adoption of FRP scrubbers will undoubtedly play a crucial role in shaping the future of responsible industry practices.

Trustworthiness is another key component in the decision-making process for industrial clients. Manufacturers of FRP scrubbers are often certified and adhere to international quality standards, ensuring that these scrubbers can be trusted to perform under pressure. High-profile case studies and endorsements from leading industrial players provide further assurance of their reliability and effectiveness. Furthermore, investing in an FRP scrubber showcases a commitment to sustainability and corporate social responsibility. By implementing such advanced pollution control equipment, companies not only comply with environmental regulations but also demonstrate leadership in protecting the environment, thus enhancing their corporate image and trustworthiness among consumers and stakeholders. In summary, FRP scrubbers are indispensable for industries committed to robust air pollution control strategies. With notable advantages in durability, efficiency, and cost-effectiveness, they provide a comprehensive solution to modern environmental challenges. Their proven track record of performance and compliance, underpinned by expert engineering and rigorous standards, solidifies their authority in the market. For those considering an investment in air pollution control technology, FRP scrubbers represent a prudent choice rooted in both practicality and a forward-thinking approach to sustainability. My extensive involvement with these systems affirms that the strategic integration of an FRP scrubber into existing operations can yield significant benefits, aligning operational goals with environmental stewardship. As the demand for cleaner industrial processes escalates, the adoption of FRP scrubbers will undoubtedly play a crucial role in shaping the future of responsible industry practices.

Next:

Related Products