-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Impact of FRP Settlers on Renewable Energy Development

The Concept of FRP Settler An Overview

The term FRP settler refers to a specific technological solution that plays a crucial role in various industrial processes, particularly in the field of wastewater treatment and separation technologies. Understanding the concept of FRP (Fibre Reinforced Plastic) settlers is essential for professionals and stakeholders involved in environmental engineering, chemical processing, and water management. This article delves into the characteristics, applications, benefits, and challenges associated with FRP settlers.

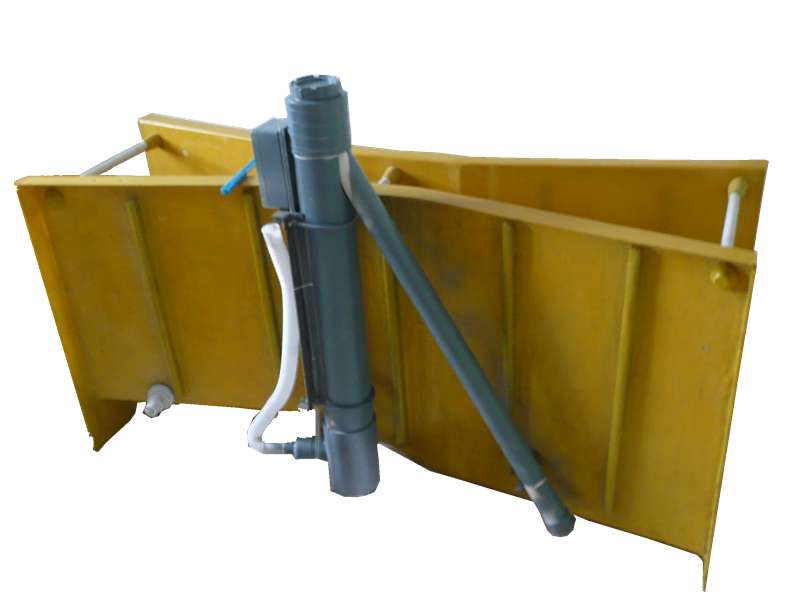

What is an FRP Settler?

An FRP settler is a type of settling tank constructed from fiber-reinforced plastic materials. FRP is known for its strength-to-weight ratio, corrosion resistance, and durability. This makes it particularly suitable for environments where traditional materials like steel or concrete may succumb to corrosion or wear over time, especially in applications involving aggressive chemicals or harsh conditions. Settlers, also referred to as sedimentation tanks, are designed to allow solid particles suspended in liquids to settle out of the suspension by gravity.

Characteristics of FRP Settlers

1. Durability and Corrosion Resistance FRP materials are inherently resistant to various chemicals, which prolongs the lifespan of the settler and decreases maintenance costs associated with traditional materials that may corrode over time.

2. Lightweight The light weight of FRP makes it easier and more cost-effective to transport and install compared to heavier metal alternatives. This feature is particularly beneficial in remote locations where heavy lift equipment may not be readily available.

3. Customizability FRP settlers can be tailored to meet specific operational requirements, with various configurations available to suit the particular needs of the application, such as varying sizes and shapes.

4. Thermal Stability FRP composites perform well across a range of temperatures, making them suitable for both cold and hot industries.

Applications of FRP Settlers

FRP settlers are utilized in a variety of industrial processes, primarily in

1. Wastewater Treatment They are commonly used in municipal and industrial wastewater treatment plants to facilitate the removal of suspended solids and other contaminants, improving water quality before discharge or reuse.

2. Chemical Processing In industries that handle corrosive chemicals, FRP settlers are employed to separate solids from liquids efficiently, thus ensuring operational safety and environmental compliance.

frp settler

3. Mining Industry Settlers are integral in separating slurries produced during mineral processing, allowing for effective recovery of valuable ores while managing waste.

4. Food and Beverage Sector Applications in this sector often require the removal of solids from liquids to ensure product quality, making FRP settlers a common choice.

Benefits of Using FRP Settlers

The adoption of FRP settlers presents several advantages

1. Cost-Effective Solution Although the initial investment may be higher than traditional materials, the long-term savings from reduced maintenance and increased operational lifespan often result in lower total cost of ownership.

2. Environmental Impact Efficiently removing solids from wastewater contributes to environmental conservation efforts and aids in meeting regulatory requirements for effluent discharge.

3. Enhanced Operational Efficiency The effectiveness of FRP settlers in separating solids can lead to higher recovery rates of valuable resources, improving overall process efficiencies.

4. Sustainability As industries are increasingly pushed towards sustainable practices, employing FRP settlers can align with corporate social responsibility goals, demonstrating a commitment to environmental stewardship.

Challenges and Considerations

Despite the numerous benefits, opting for FRP settlers does present challenges. The installation process may require specialized skills, and improper handling can lead to issues. Additionally, the initial cost may deter some installations, particularly in budget-constrained projects. It is also vital to ensure compatibility between the FRP materials and the specific chemicals involved in the process to prevent degradation or failure of the system.

Conclusion

FRP settlers are an innovative solution that addresses many of the challenges associated with traditional settling technologies. Their durability, lightweight nature, and resistance to corrosion make them ideal for various applications, particularly in wastewater treatment and industrial processing. As industries continue to advance technologies aimed at sustainability and efficiency, FRP settlers will likely play an increasingly prominent role in environmental management and resource recovery initiatives. Understanding the potential and challenges of FRP settlers will enable stakeholders to make informed decisions in their selection and implementation.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025