-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

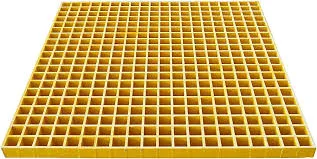

frp settler

The Concept of FRP Settler A Comprehensive Overview

The term FRP settler refers to a sophisticated system used in various industrial processes, particularly in the fields of water treatment, chemical processing, and wastewater management. FRP stands for Fiber Reinforced Plastic, a composite material known for its exceptional strength-to-weight ratio and corrosion resistance. Settlers, on the other hand, are crucial components in the separation processes, allowing for the effective removal of solids from liquids. By merging these two concepts, the FRP settler becomes a pivotal tool in enhancing operational efficiency and sustainability in industrial applications.

FRP settlers are designed to facilitate the sedimentation process, where particles suspended in a liquid settle down under the influence of gravity. This process is essential in various industries where the separation of solids from liquids is required. FRP's lightweight and durable characteristics make these settlers an ideal component for such applications. Unlike traditional materials such as steel or concrete, FRP is less prone to corrosion, which is particularly beneficial in environments where chemicals are present.

The Concept of FRP Settler A Comprehensive Overview

In terms of design, FRP settlers come in various shapes and sizes to accommodate specific needs. They can be customized to optimize the settling process depending on the type of particles and the characteristics of the liquid being treated. The design often includes features such as inclined plates or membrane technology, which enhance the settling rate and increase the surface area for sedimentation. These design innovations allow for a smaller footprint in facilities, which is particularly advantageous in urban settings where space is limited.

frp settler

The process of sedimentation in FRP settlers begins when a mixture of solid and liquid enters the settler. As the liquid flows through the unit, gravity draws the solid particles downwards. Over time, these particles accumulate at the bottom, forming a sludge layer. The clarified liquid emerges from the top of the settler, ready for further processing or discharge. This efficiency not only helps in meeting regulatory compliance but also contributes to overall resource conservation.

Another important aspect of FRP settlers is their environmental impact. By facilitating effective solid-liquid separation, these systems help reduce pollutants released into the environment. This is particularly crucial in industries with stringent discharge regulations. Furthermore, the ability to recover valuable solids from wastewater enhances the sustainability of operations, promoting a circular economy where waste materials are repurposed rather than discarded.

Moreover, the hydrodynamic design of FRP settlers plays a critical role in optimizing performance. Engineers often take into account factors such as flow rate, particle size, and viscosity to ensure that the settlers operate at peak efficiency. Computational fluid dynamics (CFD) simulations are commonly employed during the design phase to predict how liquids and solids will interact within the settler, allowing for fine-tuning of the system before it is deployed in a real-world setting.

In conclusion, FRP settlers represent a significant advancement in the realm of industrial liquid-solid separation. Their unique properties, coupled with advanced design capabilities, offer a robust solution for various applications, from wastewater treatment to chemical processing. As industries move towards more sustainable practices, the importance of such innovative technologies cannot be overstated. The development and implementation of FRP settlers are exemplary of how engineering solutions can address both operational efficiency and environmental responsibility, paving the way for a cleaner and more sustainable future.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025