-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 13, 2025 12:10

Back to list

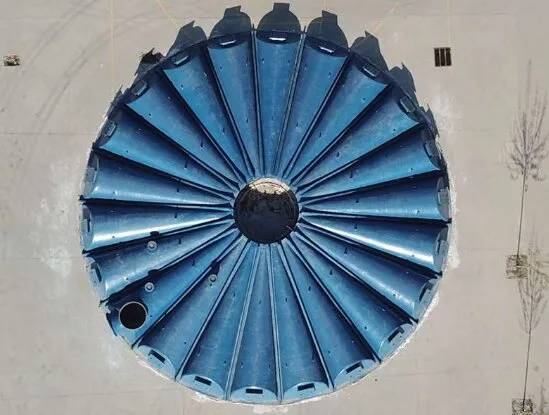

frp settler

Fiber Reinforced Plastic (FRP) settlers have emerged as a revolutionary innovation within industrial and environmental engineering sectors, standing out as indispensable assets across diverse applications. By marrying advanced composite materials with engineering innovation, FRP settlers are engineered to optimize sedimentation processes, maximizing efficiency while minimizing environmental impacts. Drawing from real-world applications and authoritative insights, these structures exemplify exceptional performance in waste management and water treatment.

Moreover, the installation and maintenance process of FRP settlers is simplified compared to more traditional materials. Their lightweight nature reduces transportation costs and facilitates easier handling during setup. Reduced assembly and maintenance time translates directly to decreased downtime, an invaluable advantage in continuous processing environments. Operators and technicians find FRP systems straightforward to manage, with maintenance schedules less frequent and less daunting than those required by metal or concrete alternatives. Seasoned professionals in the field advocate for the transition to FRP settlers as a strategic move towards sustainable engineering practices. Their life cycle benefits are complemented by a smaller environmental footprint compared to older, traditional systems. As industries pivot towards greener technologies, the integration of FRP settlers represents a commitment to sustainable development and ecological responsibility. To realize the full potential of FRP settlers, stakeholders are encouraged to engage with experts who provide comprehensive assessments and customized solutions. This ensures that each FRP settler installation is optimized for performance, delivering maximized returns on investment. By investing in FRP technology, businesses not only bolster their operations but also establish themselves as leaders in innovation and environmental stewardship.

Moreover, the installation and maintenance process of FRP settlers is simplified compared to more traditional materials. Their lightweight nature reduces transportation costs and facilitates easier handling during setup. Reduced assembly and maintenance time translates directly to decreased downtime, an invaluable advantage in continuous processing environments. Operators and technicians find FRP systems straightforward to manage, with maintenance schedules less frequent and less daunting than those required by metal or concrete alternatives. Seasoned professionals in the field advocate for the transition to FRP settlers as a strategic move towards sustainable engineering practices. Their life cycle benefits are complemented by a smaller environmental footprint compared to older, traditional systems. As industries pivot towards greener technologies, the integration of FRP settlers represents a commitment to sustainable development and ecological responsibility. To realize the full potential of FRP settlers, stakeholders are encouraged to engage with experts who provide comprehensive assessments and customized solutions. This ensures that each FRP settler installation is optimized for performance, delivering maximized returns on investment. By investing in FRP technology, businesses not only bolster their operations but also establish themselves as leaders in innovation and environmental stewardship.

Next:

Related Products