-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 01:57

Back to list

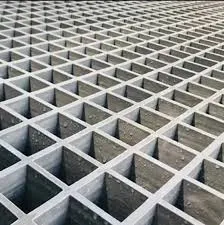

frp settler

Choosing the right equipment for wastewater treatment is crucial in ensuring both efficiency and effectiveness in purification processes. FRP (Fiberglass Reinforced Plastic) settlers stand out as a pivotal element in the treatment procedure, providing a unique combination of resilience, efficiency, and cost-effectiveness that traditional materials simply cannot match.

From a technical perspective, FRP settlers excel in providing superior separation efficiency. Their smooth surface finish minimizes sludge buildup and ensures that solids are effectively settled without excessive retention time. This efficiency contributes to an overall reduction in the footprint of treatment facilities, freeing up valuable space while optimizing operational flow. Advanced manufacturing techniques enhance the structural design of FRP settlers, further improving their capability to handle varying loads and flow rates without compromising performance. Furthermore, the sustainability of FRP as a material cannot be overlooked. With an increasing focus on environmentally friendly and sustainable practices, FRP settlers contribute positively due to their long lifespan and reduced need for maintenance and replacement. This sustainability makes them an ideal choice for organizations aiming to achieve green certifications and adhere to global environmental standards. The authority and trustworthiness of FRP settlers are well-backed by industry studies and real-world applications. Numerous case studies highlight their successful implementation across various industries, showcasing consistent performance and reliability. Industrial experts and engineers frequently recommend FRP settlers for both new setups and refurbishment projects, reflecting their trust and authoritative standing in the field of wastewater treatment. In conclusion, FRP settlers represent a modern solution to traditional wastewater treatment challenges. Their unique combination of durability, efficiency, and environmental friendliness makes them an optimal choice for industry leaders looking to enhance their treatment processes. As wastewater management continues to evolve, FRP settlers remain at the forefront, offering a blend of innovation and reliability that ensures clean, efficient, and sustainable operations.

From a technical perspective, FRP settlers excel in providing superior separation efficiency. Their smooth surface finish minimizes sludge buildup and ensures that solids are effectively settled without excessive retention time. This efficiency contributes to an overall reduction in the footprint of treatment facilities, freeing up valuable space while optimizing operational flow. Advanced manufacturing techniques enhance the structural design of FRP settlers, further improving their capability to handle varying loads and flow rates without compromising performance. Furthermore, the sustainability of FRP as a material cannot be overlooked. With an increasing focus on environmentally friendly and sustainable practices, FRP settlers contribute positively due to their long lifespan and reduced need for maintenance and replacement. This sustainability makes them an ideal choice for organizations aiming to achieve green certifications and adhere to global environmental standards. The authority and trustworthiness of FRP settlers are well-backed by industry studies and real-world applications. Numerous case studies highlight their successful implementation across various industries, showcasing consistent performance and reliability. Industrial experts and engineers frequently recommend FRP settlers for both new setups and refurbishment projects, reflecting their trust and authoritative standing in the field of wastewater treatment. In conclusion, FRP settlers represent a modern solution to traditional wastewater treatment challenges. Their unique combination of durability, efficiency, and environmental friendliness makes them an optimal choice for industry leaders looking to enhance their treatment processes. As wastewater management continues to evolve, FRP settlers remain at the forefront, offering a blend of innovation and reliability that ensures clean, efficient, and sustainable operations.

Next:

Related Products