-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

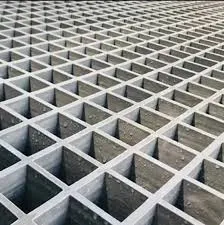

frp sheet

FRP Sheets Revolutionizing Modern Construction and Design

Fiber Reinforced Polymer (FRP) sheets have emerged as a game-changing material in the fields of construction and design. Composed of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid, FRP sheets offer numerous advantages over traditional building materials. As industries seek lighter, stronger, and more durable solutions, the popularity of FRP continues to soar.

One of the most significant advantages of FRP sheets is their high strength-to-weight ratio. They are incredibly light while maintaining exceptional strength, making them ideal for applications where weight is a critical factor. This property is particularly beneficial in sectors such as aerospace, automotive, and civil engineering, where reducing weight can lead to improved fuel efficiency, reduced emissions, and enhanced overall performance.

FRP Sheets Revolutionizing Modern Construction and Design

Furthermore, FRP sheets offer design flexibility that is hard to match. They can be easily molded into various shapes and sizes, allowing architects and engineers to push the boundaries of their designs. This adaptability is particularly advantageous in modern architecture, where innovative and aesthetically pleasing structures are in high demand. FRP sheets can be used for everything from cladding and facades to flooring and furniture, enabling the creation of unique, functional spaces that stand out.

frp sheet

Another compelling feature of FRP sheets is their thermal insulation properties. They have low thermal conductivity, which helps maintain comfortable indoor temperatures and reduces energy consumption for heating or cooling. This quality is increasingly important as building codes become stricter regarding energy efficiency. By integrating FRP sheets into building designs, developers can achieve both functional and sustainable solutions.

Moreover, the ease of installation of FRP sheets cannot be overlooked. Their lightweight nature simplifies transportation and on-site handling, reducing labor costs and time required for installation. Many FRP sheets can be cut to size and assembled quickly, making them a preferred choice for projects requiring rapid completion.

As industries continue to explore sustainable practices, the use of FRP sheets aligns perfectly with eco-friendly initiatives. Manufacturers are now producing FRP materials from recycled components, further reducing the environmental impact. Additionally, because FRP sheets are lightweight, they also lead to lower transportation emissions, contributing to a greener supply chain.

However, it’s important to note that, despite their many benefits, FRP sheets do come with considerations regarding cost and long-term performance. While their upfront costs might be higher compared to traditional materials, the overall lifecycle cost, in terms of maintenance and longevity, often proves to be beneficial. Furthermore, the proper installation of FRP sheets is crucial to ensure that they perform as expected and achieve their intended lifespan.

In conclusion, FRP sheets represent a significant advancement in material science, providing solutions that are not only functional but also environmentally sustainable. Their combination of lightweight strength, durability, corrosion resistance, design flexibility, and insulation properties makes them an ideal choice for modern construction and design. As technology continues to evolve, and as industries strive for greater efficiency and sustainability, the future of FRP sheets looks brighter than ever, paving the way for innovative construction practices that will shape our built environment for generations to come.