-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

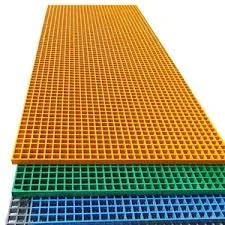

FRP Spray Pipe Applications and Benefits in Industrial Settings

The Importance of FRP Spraying Pipes in Modern Industries

In today's fast-paced industrial landscape, the demand for robust, durable, and efficient materials is paramount. Among these materials, Fiber Reinforced Plastic (FRP) has emerged as a game-changer, particularly in the manufacturing of spraying pipes. These pipes, known for their versatility and resilience, play a crucial role in various applications ranging from agriculture to industrial processes.

What are FRP Spraying Pipes?

FRP spraying pipes are composite materials consisting of a polymer matrix reinforced with fibers—most commonly glass fibers. This combination endows the pipes with exceptional strength, lightweight properties, and excellent resistance to corrosion, making them ideal for challenging environments. The spraying mechanism typically involves coating or applying materials through these pipes, allowing for precise delivery in several industrial processes.

Advantages of FRP Spraying Pipes

1. Corrosion Resistance One of the significant advantages of FRP is its resistance to corrosion. Traditional metal piping systems can degrade over time when exposed to various chemicals, which is a common scenario in industries such as chemical processing or wastewater treatment. FRP spraying pipes, however, can withstand aggressive environments without rusting or deteriorating, reducing maintenance costs and downtime.

2. Lightweight The lightweight nature of FRP makes it easier to handle and install compared to traditional piping materials like steel or concrete. The reduced weight not only simplifies transportation but also lessens the structural load on supporting structures, making it easier to incorporate into existing designs without extensive modifications.

frp spraying pipe

3. Customizability FRP spraying pipes can be tailored to meet specific application requirements. Manufacturers can adjust the resin type, fiber content, and pipe dimensions according to the industry needs, resulting in a product that delivers optimal performance for various environmental conditions.

4. Thermal and Electrical Insulation Unlike metallic pipes, FRP provides excellent thermal insulation, helping to manage temperature changes effectively. Additionally, it is a non-conductive material, making it safer for applications where electrical insulation is crucial.

5. Cost-Effectiveness While the initial investment for FRP spraying pipes may be higher than conventional materials, the long-term savings on maintenance and replacement highlight their cost-effectiveness. The durability and resistance to damage reduce the need for frequent repairs or replacements, thereby ensuring a better return on investment over time.

Applications of FRP Spraying Pipes

The applications of FRP spraying pipes are vast and varied. In agriculture, they are used for irrigation systems, delivering water and nutrients to crops with precision. In the construction industry, these pipes are part of spraying systems used for protecting structures from fire and corrosion. Furthermore, they find applications in the aerospace and automotive industries, where lightweight materials contribute significantly to fuel efficiency and performance.

Conclusion

In conclusion, FRP spraying pipes are revolutionizing the way industries approach fluid transfer and handling. Their myriad benefits—from corrosion resistance to lightweight properties—make them an indispensable component in modern industrial applications. As the demand for innovative materials continues to grow, the role of FRP spraying pipes will undoubtedly expand, paving the way for more efficient and sustainable industrial processes. Embracing this technology today ensures a competitive edge for businesses in the ever-evolving market landscape.