-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

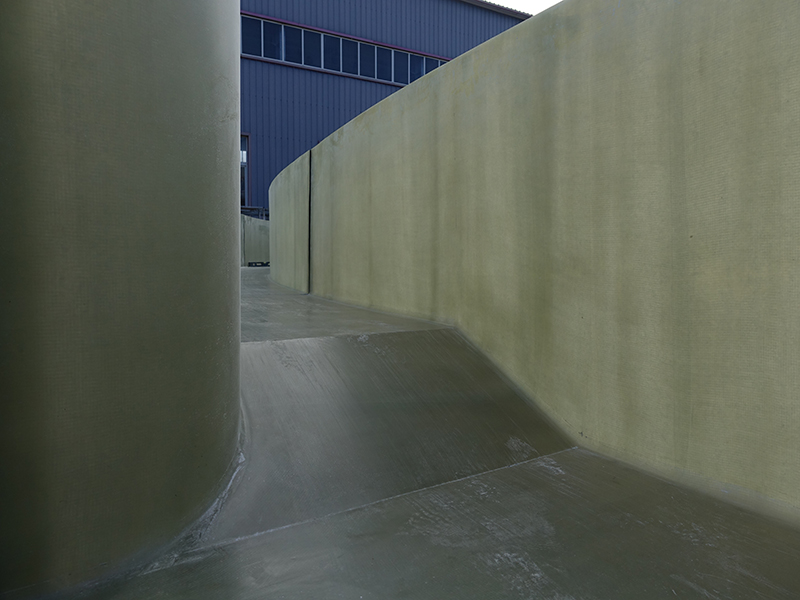

frp spraying pipe

Understanding FRP Spraying Pipes A Breakthrough in Composite Materials

The rise of composite materials has revolutionized various industries, particularly regarding durability and performance. Among these innovations is the FRP (Fiber Reinforced Plastic) spraying pipe, a remarkable solution that has transformed the way we approach piping systems in diverse applications, including construction, chemical processing, and water management.

Understanding FRP Spraying Pipes A Breakthrough in Composite Materials

The manufacturing process of FRP pipes involves a spraying technique where resin and fibrous materials are combined and sprayed onto a mold to form the desired pipe shape. This method not only ensures a uniform thickness across the pipe but also allows for the incorporation of different materials to enhance specific attributes, such as flexibility or heat resistance. As a result, FRP spraying pipes can be customized to meet the unique demands of various applications, whether in high-pressure environments or where high-temperature resistance is required.

frp spraying pipe

In terms of performance, FRP pipes exhibit excellent flow characteristics. Their smooth inner surfaces reduce friction, thereby enhancing fluid flow and minimizing energy consumption in pumping systems. This feature is particularly beneficial in water treatment facilities and industrial processes where efficiency is paramount. Moreover, the lightweight nature of FRP facilitates easier handling and installation, which can lead to significant time and labor savings on construction sites.

The environmental impact of using FRP spraying pipes should also be considered. The longevity and durability of these pipes contribute to sustainability efforts by reducing the need for frequent replacements and minimizing waste. Furthermore, many manufacturers are now focusing on using recycled materials in the production of FRP, thereby aligning with the global push towards environmentally friendly practices.

In conclusion, FRP spraying pipes are a testament to the advancements in composite materials technology. Their unique properties, such as corrosion resistance, customizability, and efficiency in fluid transportation, make them an attractive choice for modern piping solutions in a variety of industries. As the demand for durable, sustainable materials continues to grow, FRP pipes are poised to play a critical role in shaping the future of infrastructure development. Whether in the construction of new facilities or the upgrading of existing systems, FRP technology will undoubtedly contribute to achieving higher performance standards while minimizing environmental impact.