-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

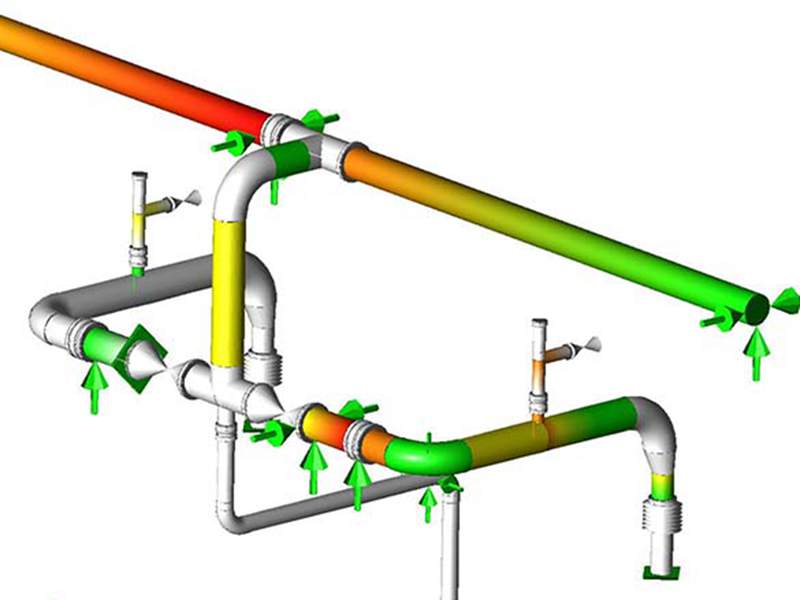

FRP Spraying Pipe Innovations for Enhanced Application Efficiency and Durability

The Advantages of FRP Spraying Pipes A Modern Solution for Various Industries

Fiber Reinforced Polymer (FRP) piping systems have gained significant attention across various industries, thanks to their unique properties and advantages over traditional materials like steel or PVC. The development of FRP spraying pipes has revolutionized the way industries manage fluid transport. In this article, we will explore the benefits and applications of FRP spraying pipes, highlighting why they are becoming a preferred choice in today's marketplace.

Understanding FRP

FRP pipes are made from a composite material that combines a polymer matrix with reinforcement fibers, typically glass or carbon. This combination results in a lightweight, strong, and durable product that can withstand harsh environmental conditions. The spraying method of creating FRP pipes involves applying a resin mixed with reinforcement fibers directly onto a mold, forming a pipe with superior mechanical properties and excellent corrosion resistance.

Key Advantages of FRP Spraying Pipes

1. Corrosion Resistance One of the most significant advantages of FRP spraying pipes is their resistance to corrosion. Unlike traditional metal pipes that can rust over time, FRP pipes do not corrode when exposed to a variety of chemicals and aggressive environments. This makes them ideal for industries such as chemical processing, wastewater management, and marine applications.

2. Lightweight FRP pipes are considerably lighter than their metal counterparts, making them easier to handle, transport, and install. This lightweight nature not only reduces labor costs but also decreases the overall load on support structures, allowing for more efficient designs in various applications, including construction and oil and gas transportation.

3. High Strength-to-Weight Ratio The use of composite materials gives FRP pipes an excellent strength-to-weight ratio, making them strong enough to withstand high internal pressures while remaining light. This quality is crucial in applications where pressure fluctuations can occur, such as water delivery systems and industrial processing facilities.

frp spraying pipe

4. Thermal Insulation FRP pipes provide good thermal insulation, helping to maintain temperature in fluid transport. This attribute is especially beneficial in processes that require specific temperature conditions, avoiding heat loss in cooling systems or temperature fluctuations in chemical processes.

5. Flexibility in Design The ability to customize FRP pipes in various sizes, shapes, and diameters is a significant advantage in terms of design flexibility. Industries can design piping systems that fit specific operational needs, leading to more efficient layouts and reduced material wastage.

6. Cost-Effectiveness Although the initial investment for FRP spraying pipes may be higher than traditional materials, the long-term savings due to reduced maintenance costs, longer lifespan, and lower installation efforts make them a cost-effective choice. Their durability also means that replacement frequencies are lower, translating to further savings over time.

Applications of FRP Spraying Pipes

Due to their outstanding properties, FRP spraying pipes are employed in a multitude of applications, including

- Chemical Processing Plants Handling corrosive substances safely and efficiently. - Wastewater Treatment Facilities Withstanding the harsh conditions of sewer systems. - Oil and Gas Industries Transporting fluids safely under challenging environmental conditions. - Marine Engineering Providing corrosion resistance in seawater contexts. - Civil Engineering Projects Used in drainage systems and as part of modern infrastructure.

Conclusion

FRP spraying pipes represent a technological advancement that addresses many challenges faced by industries today. Their superior corrosion resistance, lightweight nature, high strength, and versatility for various applications position them as a preferable choice. As industries continuously seek ways to enhance efficiency and sustainability, FRP piping systems will likely play a pivotal role in shaping the future of fluid transport. By embracing these innovative solutions, companies can not only improve their operational processes but also contribute to long-term environmental sustainability.