-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

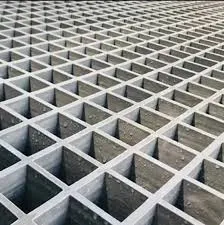

Exploring the Benefits of FRP Spraying Pipes in Modern Applications

The Versatility and Applications of FRP Spraying Pipes

Fiberglass Reinforced Plastic (FRP) has revolutionized various industries, and one of its notable applications is in the form of spraying pipes. These pipes, characterized by their lightweight, high strength, and corrosion resistance, are becoming increasingly popular in industries ranging from agriculture to construction. This article delves into the features, benefits, and diverse applications of FRP spraying pipes.

What is FRP?

Fiberglass Reinforced Plastic is a composite material made of a polymer matrix reinforced with fibers, typically glass fibers. This combination provides FRP with remarkable mechanical properties. The efficiency of FRP stems from its ability to be molded into various shapes while maintaining durability and strength, making it an excellent choice for piping applications.

Benefits of FRP Spraying Pipes

1. Corrosion Resistance One of the most significant advantages of FRP is its resistance to corrosion. Unlike traditional metal pipes, FRP does not rust or degrade when exposed to chemicals, making it ideal for environments where corrosive substances are prevalent.

2. Lightweight FRP spraying pipes are significantly lighter than steel or concrete alternatives. This characteristic not only simplifies handling and transportation but also reduces installation costs, as less intensive structural support is necessary.

3. High Strength-to-Weight Ratio Although lightweight, FRP pipes offer exceptional strength, capable of withstanding high pressures and physical stress. This quality makes them suitable for a wide range of applications, from agricultural irrigation systems to industrial operations.

4. Thermal Insulation FRP provides natural thermal insulation due to its composition, reducing energy costs in applications that involve temperature-sensitive contents.

5. Customizable Designs FRP can be molded into different shapes and sizes, allowing for customized piping systems tailored to specific application needs.

frp spraying pipe

Applications of FRP Spraying Pipes

1. Agriculture In agriculture, FRP spraying pipes are increasingly utilized for irrigation systems. Their resistance to chemical fertilizers and pesticides ensures longevity and reliability in conveying liquids. The lightweight nature facilitates easy installation and maintenance, crucial for extensive farming operations.

2. Chemical Processing In chemical industries, where pipes often come in contact with harsh substances, FRP spraying pipes provide a reliable solution. Their ability to resist corrosion and the infiltration of aggressive chemicals ensures efficient and safe transportation of various materials.

3. Water Treatment FRP pipes play a crucial role in water treatment facilities. They are used for delivering and distributing treated water, as their hygiene standards are high, preventing contamination and ensuring safe drinking water.

4. Construction In the construction industry, FRP spraying pipes are increasingly used for drainage and sewage systems. Their lightweight nature allows for easy installation, while their corrosion resistance ensures a long lifespan, reducing the need for frequent replacements.

5. Mining In mining operations, FRP pipes are ideal for transporting slurries and other mining fluids. They can endure the harsh conditions often present in mines, providing a durable and long-lasting solution.

Conclusion

FRP spraying pipes offer a range of advantages that make them a superior choice over traditional piping materials. Their lightweight, corrosion-resistant properties, along with customizable designs, make them suitable for a variety of industries, including agriculture, chemical processing, water treatment, construction, and mining. As industries continue to seek efficient and sustainable solutions, the role of FRP pipes in enhancing operational efficiency and durability is set to grow, marking a significant step forward in materials technology.

In summary, FRP spraying pipes represent a blend of innovation and practicality, empowering industries to operate effectively while reducing maintenance costs and enhancing safety in handling various fluids. As technology advances and the demand for sustainable practices increases, the reliance on FRP pipes is likely to become even more pronounced in the years to come.