-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

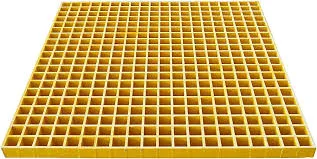

frp step

Understanding FRP Steps A Comprehensive Guide

Fiber Reinforced Polymer (FRP) has revolutionized various industries by offering innovative solutions for reinforcement and construction. The use of FRP materials in structural applications has grown significantly due to their lightweight, high strength, and corrosion-resistant properties. Understanding the steps involved in utilizing FRP can help ensure effective implementation and maximize the benefits of this advanced technology.

Step 1 Material Selection

The first step in any FRP project is selecting the appropriate type of FRP material. There are various types of FRP, including glass fiber reinforced polymer (GFRP), carbon fiber reinforced polymer (CFRP), and aramid fiber reinforced polymer (AFRP). Each type has its unique properties, such as tensile strength, durability, and resistance to chemicals. The choice depends on the specific requirements of the application, including load-bearing capacity, environmental conditions, and cost considerations.

Step 2 Design and Analysis

Once the material is selected, the next step involves comprehensive design and analysis. Engineers typically use software tools to create models and perform structural analysis to ensure that the design meets the required performance criteria. It is crucial to consider the loading conditions, environmental factors, and the overall lifespan of the structure during this phase. Detailed calculations and simulations help in identifying potential weaknesses and ensuring safety and compliance with relevant codes and standards.

Step 3 Fabrication

frp step

After finalizing the design, the fabrication of FRP components takes place. This step involves the manufacturing of the FRP materials into specific shapes and sizes required for construction. Various techniques can be employed, such as pultrusion, filament winding, and hand lay-up. The choice of manufacturing process can affect the material properties, and quality control measures are essential to guarantee that the final products meet the desired specifications.

Step 4 Installation

Once the FRP components are fabricated, the next step is installation. Proper installation techniques are crucial for the performance and longevity of the FRP structures. This process may involve bonding the FRP elements to existing structures, bolting, or anchoring. It is essential that trained professionals undertake the installation to ensure adherence to safety standards and to optimize the structural performance.

Step 5 Maintenance and Monitoring

Finally, ongoing maintenance and monitoring are vital for evaluating the performance of FRP structures over time. Regular inspections can help identify any signs of wear or damage, ensuring timely repairs and prolonging the lifespan of the materials. Implementing a monitoring system can provide valuable data on the structural health and enable proactive maintenance strategies.

In conclusion, effectively utilizing FRP involves a series of structured steps from material selection to maintenance. By following these steps, engineers and construction professionals can harness the full potential of FRP, leading to enhanced safety, efficiency, and durability in structures.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025