-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp storage tank

Understanding FRP Storage Tanks Advantages and Applications

Fiberglass Reinforced Plastic (FRP) storage tanks have become increasingly popular across various industries due to their unique properties and advantages. These tanks, made from a composite material, combine the strength of fiberglass with the durability of plastic, making them ideal for storing a variety of substances, including chemicals, water, and wastewater. In this article, we will explore the benefits and applications of FRP storage tanks, emphasizing why they are a preferred choice for many industries.

What is FRP?

FRP, or Fiberglass Reinforced Plastic, is a composite material made by combining fiberglass fibers with a resin, usually polyester or vinyl ester. The result is a lightweight, strong, and corrosion-resistant material that is highly adaptable. The strength-to-weight ratio of FRP is superior to that of traditional materials like steel or concrete. This unique combination allows FRP tanks to maintain structural integrity while being significantly lighter, which simplifies transportation and installation.

Key Advantages of FRP Storage Tanks

1. Corrosion Resistance One of the primary advantages of FRP storage tanks is their excellent resistance to corrosion. Traditional metal tanks can corrode when exposed to acidic or alkaline substances, leading to expensive repairs and potentially hazardous leaks. FRP tanks, on the other hand, do not corrode, making them ideal for storing aggressive chemicals.

2. Lightweight and Durable FRP tanks are considerably lighter than their metal counterparts, which reduces shipping and installation costs. Despite their lightweight nature, FRP tanks possess remarkable durability and can withstand harsh environmental conditions. This resilience makes them suitable for a range of applications, from agricultural storage to industrial uses.

3. Customizable FRP storage tanks can be manufactured in various shapes, sizes, and colors. This customization allows industries to tailor tanks to their specific needs, whether for capacity, shape, or aesthetic purposes. This flexibility is particularly beneficial for installations with space constraints or unique design requirements.

4. Thermal Insulation FRP material offers excellent thermal insulation properties. This feature is crucial when storing temperature-sensitive materials. FRP tanks can help maintain a stable temperature for the contents inside, safeguarding them from external temperature fluctuations.

5. Minimized Maintenance FRP tanks require minimal maintenance compared to traditional storage tanks. Their resistance to rust and corrosion means that they do not necessitate frequent inspections or repairs, thereby reducing the lifetime costs associated with tank management.

frp storage tank

Applications of FRP Storage Tanks

FRP storage tanks have a broad range of applications across various industries. Here are some notable examples

1. Chemical Storage The chemical industry often utilizes FRP tanks to safely store corrosive and hazardous materials. The tanks can be designed to accommodate specific chemicals, ensuring compliance with safety regulations while minimizing the risk of spills or leaks.

2. Water and Wastewater Treatment In municipal and industrial water treatment applications, FRP tanks are used to store treated and untreated water. Their corrosion resistance makes them suitable for environments exposed to moisture and chemicals commonly found in wastewater treatment processes.

3. Agricultural Applications FRP tanks are widely employed in agriculture for storing fertilizers and pesticides. Their resistance to corrosive chemicals ensures that the materials remain safe for use without contamination.

4. Oil and Gas Industry The oil and gas sector uses FRP tanks for the storage of various fluids, including crude oil and additives. The lightweight design facilitates easier transport to remote drilling sites, while the material’s resilience extends the tank’s lifespan.

5. Food and Beverage Industry In food processing, FRP tanks can be used for storing non-corrosive liquids such as water and various food products. The material’s non-toxic properties ensure that there is no contamination, maintaining food safety standards.

Conclusion

FRP storage tanks represent a modern solution to the challenges faced by industries that require reliable storage solutions. Their unique combination of lightweight durability, corrosion resistance, and ease of customization positions them as an ideal choice for a variety of applications. As industries continue to seek innovative solutions that enhance safety and efficiency, FRP storage tanks will undoubtedly play a critical role in the future of storage technology.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

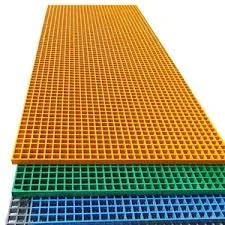

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025