-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

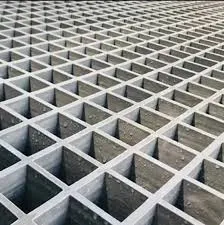

frp stub flange

Understanding FRP Stub Flanges A Comprehensive Overview

Fiberglass Reinforced Plastic (FRP) has emerged as a pivotal material in various industrial applications due to its unique combination of strength, durability, and resistance to corrosion. Among the many components fabricated from FRP, the stub flange holds significant importance, especially in pipe systems. This article will delve into the nature, applications, and advantages of FRP stub flanges.

Understanding FRP Stub Flanges A Comprehensive Overview

One of the key benefits of using FRP materials for stub flanges is their exceptional resistance to corrosion. Unlike traditional metal flanges that may corrode over time due to exposure to harsh chemicals or environmental factors, FRP stub flanges maintain their integrity and functionality. This characteristic makes them particularly suitable for industries like chemical processing, wastewater treatment, and marine applications, where exposure to corrosive substances is commonplace.

frp stub flange

Furthermore, the lightweight nature of FRP contributes to easier handling and installation compared to metal alternatives. This lightweight characteristic not only reduces transportation costs but also minimizes the structural load on supporting structures. As a result, engineers and contractors often prefer FRP stub flanges for projects that demand both durability and efficiency.

Another notable advantage is the low thermal conductivity of FRP materials. This property helps in reducing heat loss in piping systems, making them more energy-efficient. Additionally, FRP stub flanges can be customized to fit specific project needs, ensuring compatibility with existing pipe systems and enhancing overall system performance.

In conclusion, FRP stub flanges represent a robust solution to modern piping challenges, offering a reliable and efficient means of connection in various industrial applications. Their corrosion resistance, lightweight properties, and energy efficiency make them an integral component in today’s engineering endeavors. As industries continue to seek sustainable and durable materials, the importance of FRP will likely continue to grow, elevating the role of stub flanges in future applications.