-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

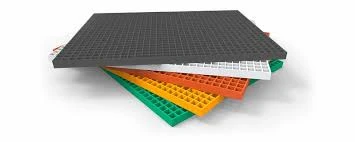

frp stub flange

Understanding FRP Stub Flanges A Comprehensive Overview

In modern engineering, composite materials have gained popularity due to their superior strength-to-weight ratios and corrosion resistance. One such material is Fiber Reinforced Polymer (FRP), which has become a crucial component in various industries, including construction, maritime, and chemical processing. Among the main components in FRP applications are stub flanges, which play a vital role in connecting piping systems. This article delves into the characteristics, advantages, and applications of FRP stub flanges.

What are FRP Stub Flanges?

FRP stub flanges are specialized components used to create joints in piping systems, especially when one pipe needs to be connected to another or to a fitting. They are designed as short sections of pipe with a flange on the end, allowing for an easy and effective interface for attachments. Typically, FRP stub flanges consist of layers of fibers, such as glass or carbon, embedded in a polymer resin, which can be tailored to resist various environmental factors.

Advantages of Using FRP Stub Flanges

1. Corrosion Resistance One of the most significant advantages of FRP stub flanges is their exceptional resistance to corrosion. Traditional materials like steel can succumb to rust and other forms of degradation when exposed to moisture or reactive chemicals. In contrast, FRP materials are impervious to a range of corrosive substances, making them ideal for use in chemical processing plants or maritime environments.

2. Lightweight Design FRP stub flanges are considerably lighter than their metal counterparts. This lightweight nature not only simplifies installation but also reduces the overall load on the supporting structures. This is particularly beneficial in applications where weight is a critical factor.

3. Low Thermal Conductivity When using metallic parts, thermal conduction can lead to energy losses and potentially harm the integrity of adjacent structures. FRP stub flanges have low thermal conductivity, minimizing heat transfer and improving energy efficiency in various applications.

frp stub flange

4. Customizability FRP materials can be manufactured in a variety of shapes, sizes, and colors, allowing engineers to customize stub flanges according to specific project requirements. This versatility can enhance the aesthetics of a project while ensuring that technical specifications are met.

5. Longevity FRP materials typically exhibit excellent durability and longevity, reducing the need for frequent replacements and maintenance. This can result in lower operational costs over the lifespan of a project.

Applications of FRP Stub Flanges

The application of FRP stub flanges spans many industries due to their unique properties. Some noteworthy examples include

- Chemical Processing In chemical plants where harsh chemicals are handled, FRP stub flanges are used to prevent leaks and corrosion, ensuring safe and efficient operation. - Water and Wastewater Management These flanges are commonly used in water treatment facilities, where resistance to corrosion is essential, given the presence of various pollutants. - Marine Applications In ships and offshore platforms, FRP stub flanges provide reliable connections that withstand the harsh saline environment, extending the life of the systems. - Pharmaceutical Industry In pharmaceutical manufacturing, hygiene and resistance to contamination are paramount. FRP materials meet these stringent requirements, making them suitable for such applications.

Conclusion

The advent of FRP stub flanges marks a significant improvement in the field of piping systems, offering numerous advantages over traditional materials. Their exceptional resistance to corrosion, lightweight design, low thermal conductivity, and reliability contribute to their widespread adoption across various industries. As technology and engineering continue to evolve, FRP stub flanges will likely play an increasing role in future infrastructure and manufacturing projects, paving the way for more efficient and durable engineering solutions. This shift not only enhances performance but also promises more sustainable practices in managing resources and minimizing environmental impacts. As industries continue to evolve, the use of FRP stub flanges will undoubtedly be a key factor in the drive toward innovation and excellence.