-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

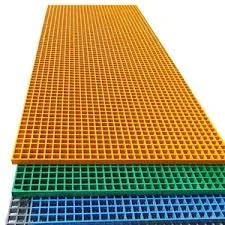

Innovative Solutions for FRP Tank Design and Applications in Various Industries

Understanding FRP Tanks Revolutionizing Storage Solutions

Fiberglass Reinforced Plastic (FRP) tanks have emerged as a pivotal component in various industries, such as water treatment, chemical storage, and agriculture. Their unique structure and properties provide significant advantages over traditional storage methods, making them an increasingly popular choice for businesses looking to enhance safety, durability, and efficiency.

What is FRP?

FRP, or Fiberglass Reinforced Plastic, is a composite material made from a polymer matrix reinforced with fibers, typically glass fibers. This combination results in a lightweight yet incredibly strong material. FRP tanks benefit from this robust construction, making them resistant to a variety of environmental conditions, including corrosion, temperature fluctuations, and impact. The resilience of FRP significantly extends the lifespan of storage solutions, offering a long-term investment for companies that require reliable infrastructure.

Advantages of FRP Tanks

1. Corrosion Resistance One of the standout features of FRP tanks is their exceptional resistance to corrosive substances. Unlike metal tanks that may rust or degrade over time when exposed to chemicals, FRP tanks maintain their integrity when storing various liquids, from water to aggressive chemicals. This characteristic not only enhances the safety of the stored materials but also reduces the need for frequent replacement or repair.

2. Lightweight and Cost-Effective Compared to conventional metal tanks, FRP tanks are considerably lighter. This lightweight nature simplifies transportation and installation, lowering associated labor costs and facilitating mobility in industrial settings. Moreover, the reduced need for heavy support structures due to their inherent strength results in overall cost savings.

frp tank

3. Customization Options FRP tanks offer extensive customization capabilities. Manufacturers can design tanks to meet specific requirements, such as size, shape, and internal fittings. This adaptability is crucial for industries that require tailored solutions for unique storage challenges.

4. Thermal Insulation FRP tanks exhibit excellent insulation properties, preventing external temperature fluctuations from affecting the stored contents. This aspect is particularly valuable for industries dealing with temperature-sensitive materials, ensuring the quality and stability of the substances held within.

5. Environmental Impact and Sustainability The production of FRP tanks can involve sustainable practices, utilizing recyclable materials in their construction. Additionally, their longevity and reduced maintenance needs contribute positively to environmental sustainability within industrial operations, minimizing waste over time.

Applications of FRP Tanks

The versatility of FRP tanks makes them suitable for a range of applications. In the water treatment industry, they are often employed for the storage of potable water, chemicals used in treatment processes, and wastewater. In the chemical and petrochemical industries, FRP tanks provide a safe method for storing corrosive substances, preventing potential leaks and environmental hazards. Additionally, agricultural sectors use FRP tanks for the storage of fertilizers and other chemicals.

Conclusion

As industries seek safer, more efficient, and cost-effective storage solutions, the adoption of FRP tanks is expected to grow. Their unique properties address numerous challenges associated with traditional storage methods, making them an attractive choice for businesses of all sizes. With their endless customization possibilities, resilience to harsh environments, and commitment to sustainability, FRP tanks represent the future of storage technology. Whether for chemical processing, water treatment, or agricultural applications, FRP tanks are set to play a crucial role in shaping how we approach storage in an increasingly complex industrial landscape.