-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 09, 2025 10:34

Back to list

Steps

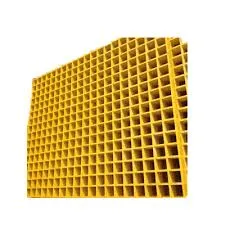

In the realm of industrial storage solutions, FRP (Fiber Reinforced Plastic) tanks stand out as an exceptionally viable option. Known for their durability, versatility, and resistance to a wide range of chemicals, these tanks have become the backbone of fluid storage in numerous industries. From wastewater treatment to chemical processing, the benefits of utilizing FRP tanks are extensive, adding substantial value to almost any operation.

The authoritarian stance of companies specializing in FRP tanks is backed by decades of experience and extensive certifications, assuring clients of the products’ quality and safety. These manufacturers adhere to stringent standards to produce tanks that meet international safety regulations—providing assurance and compliance in every unit delivered. This established authority in FRP tank production ensures that businesses can trust in the product's ability to perform reliably over time, safeguarding their operations and investments. Trust in FRP tanks is further enhanced by the positive testimonials and case studies from their widespread application across various sectors. From small enterprises to large corporations, many have attested to the tanks' efficacy in improving operational efficiency and reducing costs. By choosing FRP tanks, businesses not only invest in a storage solution but also in peace of mind, knowing their operations are shielded against potential chemical hazards and maintenance issues. In conclusion, FRP tanks present an unparalleled option for industries seeking reliable, strong, and sustainable storage solutions. Their resistance to chemicals, structural strength, and customizable nature make them indispensable. Coupled with the authority and trust garnered through expert manufacturing practices and compliance with international standards, FRP tanks stand as a testament to engineering excellence. Businesses leveraging these tanks are equipped with the assurance of safety, efficiency, and sustainability, illustrating why FRP tanks are the preferred choice for modern industrial storage needs.

The authoritarian stance of companies specializing in FRP tanks is backed by decades of experience and extensive certifications, assuring clients of the products’ quality and safety. These manufacturers adhere to stringent standards to produce tanks that meet international safety regulations—providing assurance and compliance in every unit delivered. This established authority in FRP tank production ensures that businesses can trust in the product's ability to perform reliably over time, safeguarding their operations and investments. Trust in FRP tanks is further enhanced by the positive testimonials and case studies from their widespread application across various sectors. From small enterprises to large corporations, many have attested to the tanks' efficacy in improving operational efficiency and reducing costs. By choosing FRP tanks, businesses not only invest in a storage solution but also in peace of mind, knowing their operations are shielded against potential chemical hazards and maintenance issues. In conclusion, FRP tanks present an unparalleled option for industries seeking reliable, strong, and sustainable storage solutions. Their resistance to chemicals, structural strength, and customizable nature make them indispensable. Coupled with the authority and trust garnered through expert manufacturing practices and compliance with international standards, FRP tanks stand as a testament to engineering excellence. Businesses leveraging these tanks are equipped with the assurance of safety, efficiency, and sustainability, illustrating why FRP tanks are the preferred choice for modern industrial storage needs.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025