-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

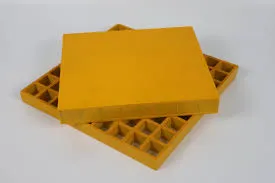

Exploring the Advantages and Applications of FRP Tee Connections in Construction

Understanding FRP Tee A Comprehensive Overview

Fiber Reinforced Polymer (FRP) is an innovative composite material that combines the lightweight properties of polymers with the high strength of fibers, such as carbon, glass, or aramid. Among the various components that can be manufactured from FRP, the FRP tee plays a crucial role in various engineering applications, especially in construction, plumbing, and industrial settings.

What is an FRP Tee?

An FRP tee is a type of fitting used to create branching points in piping systems. It resembles the letter T, allowing a main pipeline to split into two separate paths. The versatility and strength of FRP tees make them an essential component in conveying fluids, air, and other materials in different industries.

Advantages of FRP Tees

1. Corrosion Resistance One of the standout features of FRP materials is their resistance to corrosion. Unlike traditional metal fittings, FRP tees do not rust or degrade when exposed to harsh chemicals or environmental conditions. This property is particularly beneficial in industries such as chemical processing and wastewater treatment, where systems are subjected to corrosive substances.

2. Lightweight FRP tees are significantly lighter than their metal counterparts. This characteristic simplifies handling, reduces transportation costs, and makes installation easier, especially in complex projects where minimizing weight can facilitate engineering challenges.

3. High Strength-to-Weight Ratio Although lightweight, FRP tees possess an impressive strength-to-weight ratio. This quality ensures that they can withstand high pressure and maintain structural integrity without the bulk typically associated with metal fittings.

4. Thermal Insulation FRP materials have lower thermal conductivity compared to metals, making them suitable for applications where temperature control is essential. This feature is particularly useful in environments that require sensitive temperature management, as it helps to prevent heat loss or gain in piping systems.

frp tee

5. Customizability FRP tees can be manufactured in various shapes, sizes, and configurations to meet the specific needs of a project. This flexibility allows engineers to design systems that perfectly fit the requirements of their applications, optimizing performance and efficiency.

Applications of FRP Tees

FRP tees are used across various industries due to their advantageous characteristics. Some notable applications include

- Water and Wastewater Management In municipal and industrial water systems, FRP tees are commonly used to direct flow and manage distribution effectively. Their resistance to corrosion makes them ideal for environments exposed to harsh chemicals.

- Chemical Processing Many chemical plants rely on FRP tee fittings to transport corrosive substances safely. These fittings maintain integrity over time, reducing maintenance costs and downtime.

- Oil and Gas In the oil and gas sector, FRP tees are employed in pipelines for transporting fluids. Their lightweight nature facilitates installation and reduces the load on existing infrastructure.

- Marine Applications The marine industry also benefits from FRP tees due to their resistance to seawater corrosion and ability to withstand harsh environmental conditions.

Conclusion

The adoption of FRP tees in various industries highlights the growing recognition of the benefits offered by composite materials. As industries continue to seek out innovative solutions for piping systems, FRP tees stand out as a reliable and efficient choice. Their combination of strength, durability, and corrosion resistance not only enhances the longevity of infrastructure but also contributes to overall cost savings and sustainability in engineering practices. As technology advances, the production and application of FRP fittings are expected to evolve, presenting new opportunities and improvements in the field of composite materials.