-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding the Dynamics of FRP Transition in Modern Applications and Technologies

Understanding FRP Transition A Key Component in Modern Technology

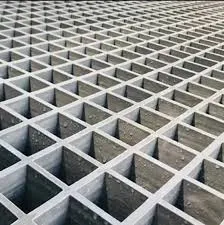

In recent years, the term FRP transition has gained significant traction within various sectors, especially in the fields of engineering, computing, and telecommunications. FRP, which stands for Fiber Reinforced Polymer, represents a composite material made up of a polymer matrix reinforced with fibers. Typically, these fibers are made from materials such as glass, carbon, or aramid, which provide remarkable strength and durability. This article explores the concept of FRP transition, its implications, benefits, and applications in modern technology.

What is FRP Transition?

FRP transition refers to the process and methods employed when shifting from traditional materials to advanced composite materials, specifically Fiber Reinforced Polymers. This transition is pivotal for organizations looking to enhance performance, reduce weight, and improve the longevity of their products. The FRP transition encompasses several stages, including material selection, design adaptation, processing changes, and life cycle implications.

The Importance of FRP Transition

As industries evolve, the demand for more efficient, lighter, and more durable materials has surged. Traditional materials like steel and aluminum, while strong, are often heavy and can be susceptible to corrosion and fatigue. FRP offers a solution by providing high strength-to-weight ratios and excellent resistance to environmental factors, such as moisture and chemicals.

Moreover, the transition to FRP is aligned with current trends towards sustainability and responsible manufacturing. FRP materials can propagate less waste during production and often involve recycling aspects. This fits seamlessly into the growing emphasis on green technologies and practices across many industries.

Benefits of FRP Transition

The benefits of transitioning to FRP materials are manifold

1. Lightweight One of the most significant advantages of FRP is its lightweight nature. This property is particularly beneficial in the aerospace and automotive sectors, where reducing weight can lead to significant fuel savings and increased efficiency.

2. Corrosion Resistance FRP materials are resistant to corrosion and do not suffer from rusting, making them ideal for use in harsh environments such as marine applications, chemical plants, and construction in coastal areas.

3. Design Flexibility The versatility of FRP materials allows for innovative designs that would be challenging or impossible with traditional materials. This flexibility can result in more aesthetically pleasing and functional products.

frp transition

4. High Strength Despite their lightness, FRP materials possess remarkable tensile strength, making them suitable for high-load applications.

5. Ease of Maintenance FRP structures often require less maintenance than their traditional counterparts, which can lead to cost savings over their lifespan.

Applications of FRP Transition

The FRP transition is not just a theoretical concept; it has practical applications across various industries.

1. Construction and Infrastructure In civil engineering, FRP is used for bridge reinforcement, strengthening existing structures, and creating lightweight formwork. Its resistance to environmental factors makes it an ideal choice for structures exposed to harsh climatic conditions.

2. Aerospace Aircraft manufacturers have increasingly turned to FRP for parts such as wings and fuselages to enhance performance while reducing weight, which is crucial in the aerospace sector.

3. Automotive Industry Many car manufacturers are incorporating FRP components to create lighter and more fuel-efficient vehicles, while also improving performance characteristics.

4. Marine Applications FRP is widely used in the construction of boats and ships due to its resistance to water, ensuring longevity and reduced maintenance.

5. Sports Equipment From bicycles to tennis rackets, FRP provides the necessary balance of strength and weight, leading to improved performance in recreational and competitive sports.

Conclusion

The transition to Fiber Reinforced Polymer materials marks a significant shift in modern manufacturing and design philosophies. As industries strive for greater efficiency, sustainability, and innovation, FRP plays a crucial role in shaping the future of materials science. Embracing this transition not only provides a competitive edge but also reflects a commitment to advancing technology in an environmentally responsible manner. As research and development continue in this field, we can expect even more revolutionary applications and benefits from FRP materials in the years to come.