-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

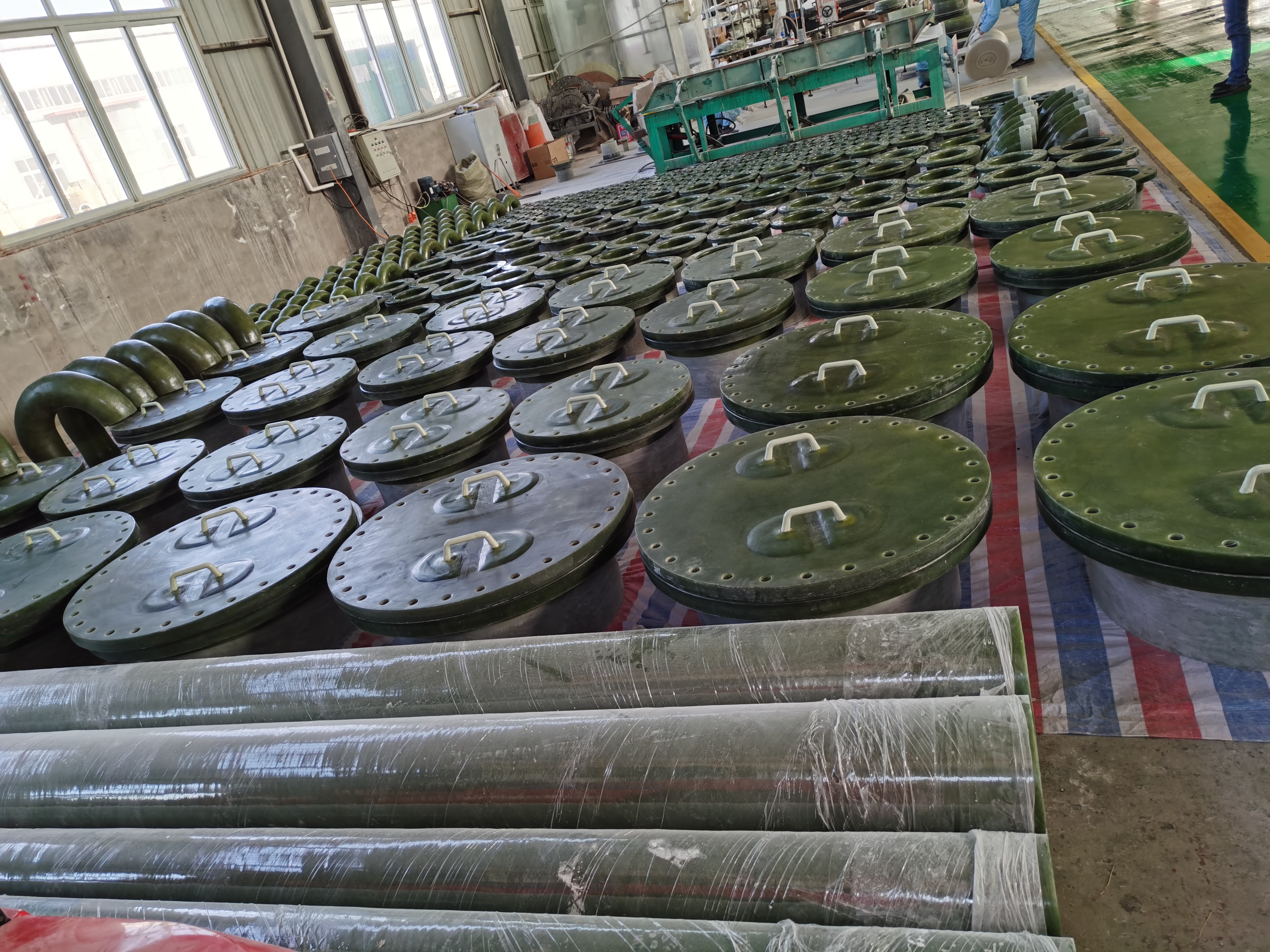

frp transport tank

Understanding FRP Transport Tanks A Modern Solution for Industrial Needs

In the realm of modern industrial storage solutions, the use of Fiber Reinforced Plastic (FRP) transport tanks has gained significant attention. These tanks are designed to store and transport a variety of liquids and can be used across a range of industries, including chemicals, food and beverage, pharmaceuticals, and wastewater management. The advantages offered by FRP transport tanks make them a compelling choice, revolutionizing how companies manage their liquid transport and storage needs.

FRP is composed of a polymer matrix reinforced with fibers, typically glass or carbon. This unique composite material offers several characteristics that enhance its suitability for transport tanks. One of the primary benefits is its exceptional strength-to-weight ratio. FRP tanks are considerably lighter than traditional materials like steel and concrete, making them easier to handle during installation and transport. This reduced weight can lead to lower transportation costs and more efficient handling processes.

Understanding FRP Transport Tanks A Modern Solution for Industrial Needs

Another advantage of FRP transport tanks is their versatility in design. Manufacturers can customize these tanks to fit specific requirements, including size, shape, and capacity. This adaptability allows businesses to optimize their storage solutions according to their unique operational needs. Furthermore, FRP tanks are available in various colors and configurations, enabling industries to identify and categorize tanks easily.

frp transport tank

In terms of maintenance, FRP tanks offer ease of care. Their smooth surfaces and resistance to chemical reactions make cleaning and upkeep straightforward, reducing the labor and resources typically required for maintenance. This simple maintenance regime contributes to operational efficiency, allowing businesses to focus on their core activities rather than on the upkeep of storage solutions.

Safety is a paramount concern in any industrial setting, and FRP transport tanks provide several safety features. The non-conductive nature of FRP helps to prevent electrical hazards, especially in environments where flammable substances are stored. Additionally, the lightweight nature of these tanks reduces the risk of accidents during handling and installation, making it safer for workers involved in transporting and setting up the tanks.

It’s also worth noting the environmental advantages of FRP transport tanks. The production and use of FRP materials can lead to lower carbon footprints when compared to traditional tank materials. FRP's long lifespan means fewer replacements and less waste, contributing to more sustainable industrial practices. As industries increasingly prioritize environmental responsibility, the adoption of FRP tanks can align with corporate sustainability goals.

In conclusion, FRP transport tanks represent an innovative solution for modern industries seeking efficient, safe, and cost-effective options for liquid storage and transportation. Their lightweight design, corrosion resistance, customization capabilities, and ease of maintenance make them an attractive choice for a variety of applications. As industries continue to evolve and face new challenges, FRP transport tanks will undoubtedly play a pivotal role in ensuring safe and reliable management of critical materials. The future of industrial storage is here, and it is constructed from the remarkable properties of fiber-reinforced plastic.