-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

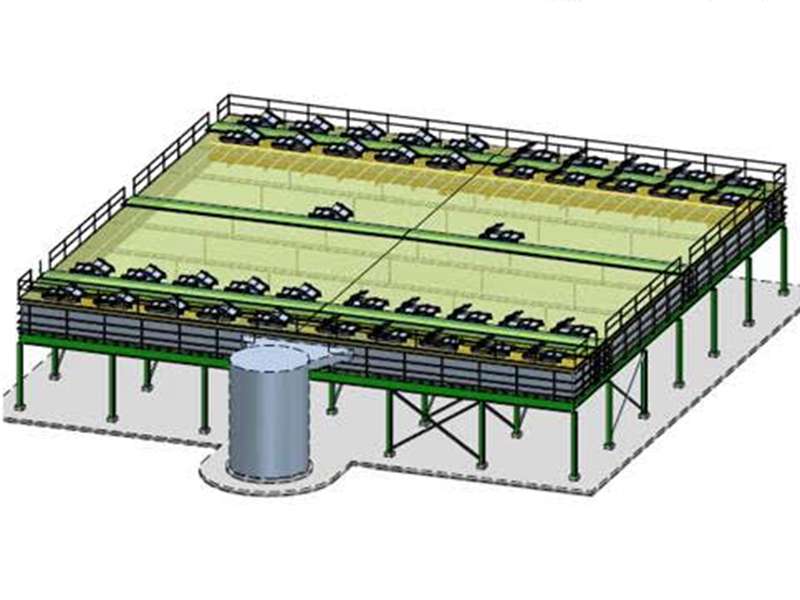

Fiberglass Reinforced Plastic Trough Covers for Enhanced Durability and Protection

The Importance of FRP Trough Covers in Modern Infrastructure

In recent years, the demand for sustainable and durable materials in construction has significantly increased. One of the innovative solutions that have gained prominence in this context is the use of Fiber Reinforced Polymer (FRP) trough covers. These covers represent a breakthrough in engineering and design, leveraging the unique properties of composite materials to address various challenges faced in urban infrastructure and industrial applications.

Understanding FRP

Fiber Reinforced Polymer is a composite material made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This composite structure provides an exceptional strength-to-weight ratio, which means that FRP materials are both lightweight and incredibly strong. They are also resistant to corrosion, which is a significant advantage over traditional materials like steel or concrete. FRP can withstand harsh environmental conditions, making it ideal for use in trough covers, drainage systems, and other infrastructure where moisture and chemicals are prevalent.

Advantages of FRP Trough Covers

1. Lightweight and Easy to Install One of the most significant advantages of FRP trough covers is their lightweight nature. Compared to traditional materials, FRP is easier to handle and install, which can lead to reduced labor costs and shorter installation times. Contractors can transport and place these covers more efficiently, making them a favored choice for both new construction and retrofitting projects.

2. Corrosion Resistance In many environments, especially those exposed to moisture and chemicals, metal fixtures can corrode over time. FRP trough covers do not suffer from such issues, significantly extending the service life of drainage and trough systems. This corrosion resistance translates to lower maintenance costs and less frequent replacements, making FRP a cost-effective long-term solution.

3. Versatility in Design FRP can be molded into various shapes and sizes, allowing for customized solutions for specific projects. This versatility means that FRP trough covers can be designed to fit unique applications, whether it is in a small municipal drainage system or a large industrial setting. Furthermore, they can be manufactured in various colors and finishes, enhancing aesthetic appeal and integrating seamlessly into the surrounding environment.

frp trough cover

4. Thermal and Electrical Insulation FRP materials offer excellent insulation properties, making them suitable for environments where temperature control is critical. Additionally, being non-conductive, they can be used in electrical applications without the risk of short circuits, making them an ideal choice for electrical enclosures and troughs.

Applications of FRP Trough Covers

FRP trough covers have found a wide array of applications across different sectors. In municipal infrastructure, they are utilized in stormwater management systems and drainage covers, ensuring safety while promoting efficient water flow. In the industrial sector, these covers are employed in chemical processing facilities, where protection from corrosive substances is paramount.

Moreover, the transportation sector benefits from FRP trough covers as they are increasingly adopted in railway and roadway systems. They contribute to safer platforms and pathways while reducing the overall weight load on bridges and structures. The use of FRP technology is also seen in the construction of pedestrian walkways and industrial flooring, where durability and safety are crucial.

Environmental Impact

The use of FRP trough covers aligns well with contemporary sustainability goals. They can be manufactured with a lower carbon footprint compared to traditional materials, and their longevity reduces the frequency of replacement, further minimizing environmental impact. Moreover, many FRP products can be recycled at the end of their life cycle, contributing to a circular economy.

Conclusion

In conclusion, FRP trough covers represent a significant advancement in materials science and engineering, offering an array of advantages over traditional materials. Their lightweight, corrosion-resistant, and versatile nature makes them an invaluable asset in modern infrastructure projects. As urban areas continue to grow and the demand for durable materials rises, FRP trough covers are poised to play an increasingly vital role in enhancing the safety and efficiency of our built environment. With ongoing advancements in technology and a focus on sustainability, the future for FRP materials looks bright, promising a transformative impact on infrastructure worldwide.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025