-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

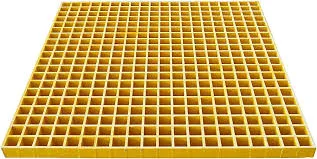

frp trough cover

Understanding FRP Trough Covers A Comprehensive Overview

In the world of construction and engineering, the materials and structures we use play a vital role in ensuring durability, safety, and efficiency. One notable advancement in this field is the use of Fiber Reinforced Polymer (FRP) trough covers. These covers have gained popularity across various industries due to their unique properties and advantages.

What is FRP?

Fiber Reinforced Polymer, commonly referred to as FRP, is a composite material made from a polymer matrix reinforced with fibers. The fibers used can be made from various materials, including glass, carbon, or aramid. This combination results in a material that is not only lightweight but also incredibly strong and resistant to various environmental factors.

Advantages of FRP Trough Covers

1. Durability One of the most significant benefits of FRP trough covers is their exceptional durability. Unlike traditional materials such as metal or concrete, FRP is resistant to corrosion, making it ideal for use in harsh environments. This is particularly important in industries such as wastewater management, where exposure to chemicals and moisture can lead to rapid deterioration of conventional materials.

2. Lightweight FRP materials are substantially lighter than metals and concrete. This reduction in weight makes transportation and installation easier and reduces the need for heavy machinery, thereby lowering overall project costs.

3. Customization FRP trough covers can be designed and manufactured to meet specific requirements. They can be produced in various shapes, sizes, and colors, allowing for high customization to suit the needs of different applications or aesthetic preferences.

4. Thermal Insulation FRP has excellent thermal insulation properties. This characteristic helps in maintaining stable temperatures in pipelines and troughs, thereby enhancing the efficiency of process systems where temperature control is critical.

frp trough cover

5. Low Maintenance Unlike traditional materials that may require regular upkeep or protective coatings, FRP trough covers are relatively low maintenance. Their resistance to rust and chemical damage means fewer resources are devoted to repairs and replacements.

Applications

FRP trough covers have a wide range of applications across various sectors. In municipal sewage systems, these covers protect access points while minimizing odor emissions and maintaining structural integrity. In the energy sector, FRP covers are commonly used in cooling towers and wastewater treatment facilities, ensuring longevity and reliability despite the challenging conditions these environments present.

In the agricultural sector, FRP trough covers provide an effective solution for irrigation systems, where they protect water supplies from contamination and evaporation. The lightweight nature of these covers also allows for easier handling and installation, which is particularly beneficial in rural or hard-to-reach locations.

Environmental Benefits

The adoption of FRP trough covers also brings about significant environmental benefits. Their longevity reduces the frequency of replacements, thus minimizing waste. Moreover, since they can be manufactured using sustainable practices, FRP materials are often designed to be recyclable or reusable, which aligns with the increasing focus on sustainable construction practices.

Conclusion

As industries continue to evolve and seek improved materials for construction and infrastructure, Fiber Reinforced Polymer trough covers stand out as a practical and efficient solution. Their superior durability, lightweight nature, and customization capabilities make them an ideal choice for diverse applications. With the added benefits of low maintenance and environmental sustainability, it's clear that FRP trough covers are paving the way for a more resilient and efficient future in engineering and construction.

In summary, the incorporation of FRP trough covers represents a significant advancement in materials technology, offering unique advantages that address both performance and environmental challenges. As the industry continues to recognize these benefits, the usage of FRP materials is expected to grow, further revolutionizing how we approach construction and infrastructure projects.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025