-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

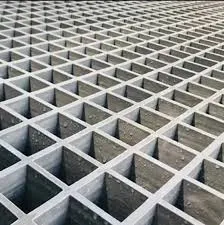

frp trough cover protective solutions for industrial applications

FRP Trough Cover Protective Solutions for Industrial Applications

In the realm of industrial operations, the need for durable and reliable protective solutions has become increasingly vital. Fiber-Reinforced Plastic (FRP) trough covers have emerged as an effective answer to many of the challenges faced in industrial settings. These innovative materials offer an array of benefits, including strength, lightweight properties, corrosion resistance, and versatility, making them an ideal choice for various applications.

Understanding FRP

Fiber-Reinforced Plastic, commonly known as FRP, is a composite material made from a polymer matrix reinforced with fibers. The most commonly used fibers are glass, carbon, or aramid, each contributing unique properties to the composite. FRP is renowned for its high strength-to-weight ratio, making it suitable for applications where traditional materials like metal or wood may falter under stress or environmental conditions.

Key Benefits of FRP Trough Covers

1. Corrosion Resistance One of the most significant advantages of FRP is its outstanding resistance to corrosion. Industrial environments often expose materials to harsh chemicals and moisture, leading to rapid degradation. FRP trough covers withstand these harsh conditions, providing a long-lasting solution that minimizes maintenance costs and downtime.

2. Lightweight and Strong Unlike traditional materials, FRP is much lighter yet offers comparable, if not superior, strength. This lightweight nature simplifies installation and handling, which can lead to increased efficiency in operations. The strength of FRP also ensures that it can endure heavy loads without bending or breaking.

3. Customizability FRP can be molded into various shapes and sizes, making it easy to customize covers to fit specific needs. This means industries can have tailored solutions that seamlessly integrate into their existing systems while providing maximum protection.

frp trough cover protective solutions for industrial applications

4. Thermal Insulation Another essential property of FRP is its thermal insulation capabilities. In industries dealing with extreme temperatures, FRP trough covers can help maintain stable internal conditions, protecting sensitive processes and materials from temperature fluctuations.

5. Safety Features Non-slip surfaces can be easily integrated into FRP trough covers, significantly improving safety in industrial environments. This is crucial, as slippery surfaces can lead to accidents and injuries, which can be costly both in terms of human welfare and operational downtime.

6. Environmental Benefits Many FRP products are manufactured using eco-friendly processes, and their longevity contributes to sustainability by reducing the frequency of replacements. In an age where environmental responsibility is paramount, the use of FRP can align with corporate sustainability goals.

Applications of FRP Trough Covers

FRP trough covers find applications across various industries. In wastewater treatment plants, for example, they protect equipment from corrosive substances while minimizing odors. In the chemical industry, FRP covers shield sensitive processes from hazardous environments, ensuring that safety and efficiency are maintained. Additionally, they are prevalent in the food processing industry, where hygiene and protection from contamination are critical.

Conclusion

In conclusion, FRP trough cover protective solutions offer numerous advantages that make them a preferred choice in industrial applications. Their strength, lightweight, corrosion resistance, and customizability make them invaluable in protecting equipment and materials from harsh conditions. As industries continue to evolve and face new challenges, the implementation of FRP solutions is expected to grow, providing improved safety, efficiency, and sustainability. As we look to the future of industrial operations, the integration of advanced materials like FRP will undoubtedly play a crucial role in driving innovation and enhancing productivity.