-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp trough cover protective solutions for industrial applications

FRP Trough Cover Protective Solutions for Industrial Applications

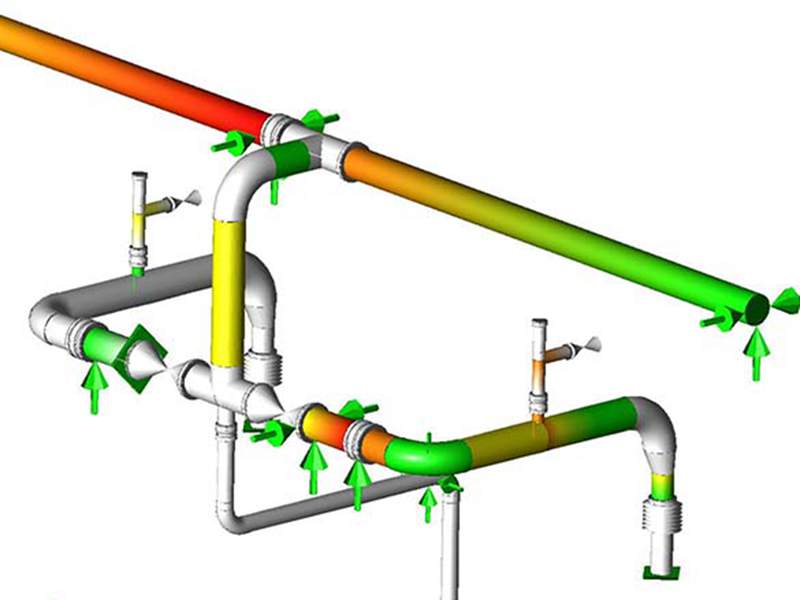

In the realm of industrial applications, ensuring safety and efficiency while mitigating risks is paramount. One often overlooked yet critical aspect of this landscape is protecting equipment and personnel from environmental hazards and operational inefficiencies. Fiberglass Reinforced Plastic (FRP) trough covers have emerged as an innovative solution, providing robust protective measures for various industrial applications.

Understanding FRP

Fiberglass Reinforced Plastic is a composite material, composed of a polymer matrix reinforced with fine fibers of glass. This combination grants FRP unique properties, including exceptional strength-to-weight ratios, corrosion resistance, and durability. It is widely recognized for its utility in industries like petrochemicals, water treatment, food processing, and power generation. FRP's versatility makes it an ideal candidate for constructing trough covers that safeguard industrial processes.

Importance of Trough Covers

Troughs in industrial settings serve various purposes, such as collecting runoff, managing liquids, or housing cables and pipes. These troughs can be vulnerable to environmental factors such as precipitation, debris, and chemical exposure. Thus, installing FRP trough covers serves multiple functions, including

1. Protection from Contaminants Covers shield the troughs from dust, debris, and contaminants that can compromise the quality of the substances within. This is especially critical in sectors like food processing, where contamination can lead to significant health risks.

2. Safety Troughs often pose tripping hazards or can become points of entrapment. Properly installed FRP covers can eliminate these hazards, providing a safe working environment for employees.

3. Thermal and Chemical Resistance In industries dealing with extreme temperatures or corrosive chemicals, FRP's resistant properties provide the necessary protection. FRP covers can withstand harsh environments that would degrade traditional materials such as metal or plastic.

4. Structural Integrity The lightweight nature of FRP does not compromise strength or durability. These covers can support considerable weight, making them suitable for environments where heavy equipment might be present.

frp trough cover protective solutions for industrial applications

Applications in Industry

FRP trough covers are adaptable across a variety of industrial applications.

- Wastewater Treatment Plants In wastewater treatment, preventing unauthorized access and exposure to harmful substances is crucial. FRP trough covers can effectively seal off areas while handling various chemicals used in the treatment process.

- Chemical Manufacturing The chemical industry often involves corrosive substances that can react with traditional materials. FRP trough covers provide a long-lasting solution that can protect both the infrastructure and the environment from hazardous spills.

- Oil and Gas Industry The oil and gas sector frequently deals with heavy machinery and potentially dangerous materials. FRP covers help protect essential pipelines and electrical conduits from environmental damage and reduce the risk of accidents.

Installation and Maintenance

Implementing FRP trough covers is relatively straightforward, though professional installation is recommended to ensure that they are fitted correctly and securely. Maintenance is also minimal due to FRP’s inherent qualities. Regular inspections are advised to check for cracks or wear, although the longevity of these covers means they typically require infrequent replacements.

Conclusion

In conclusion, FRP trough covers represent a modern solution for protecting industrial applications. Their unique characteristics cater to diverse industry needs, providing enhanced safety, durability, and efficiency. As industries continue to evolve and demand higher safety standards and material performance, the role of innovative solutions like FRP trough covers will undeniably become more prominent. Investing in these protective covers not only safeguards infrastructure and personnel but also enhances operational effectiveness across various industrial landscapes. Transitioning toward such advanced materials demonstrates a commitment to safety, innovation, and environmental stewardship in the modern industry.